#Dyeing, Drying, Finishing

etv invests over EUR 2.5 million to boost camouflage and technical printing capacity

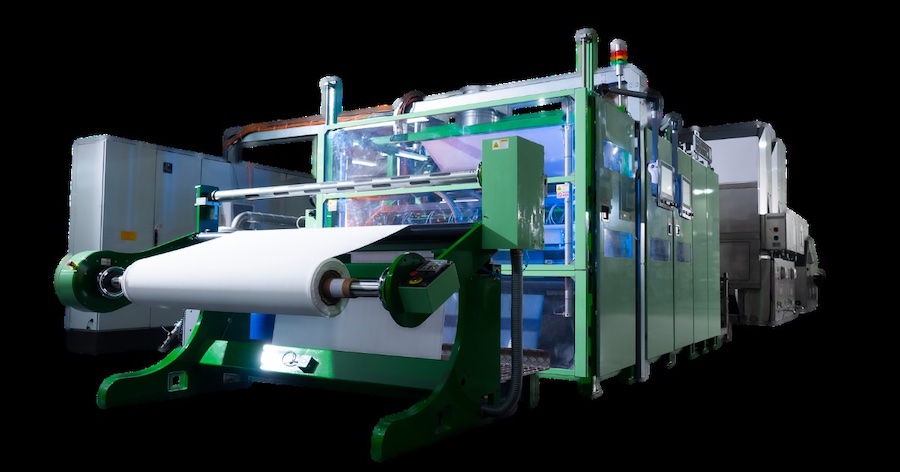

As part of its strategic expansion, etv is positioning itself as a new player in the military fabric printing market. From 2025, the company will launch a new production capacity of 2,800,000 running meters annually. The upgraded equipment will enable etv to process materials ranging from 25 to 650 g/m², including woven fabrics, nonwovens, films, and membranes, significantly enhancing its offering in the technical textiles sector.

The new rotary screen printing system boasts the latest technology, allowing etv to cater to a diverse range of applications. From lightweight, waterproof fabrics used in medical applications to heavy-duty textiles for building, construction, and home textiles, etv’s modernized printing system offers unparalleled flexibility. Additionally, the upgraded system will enable the company to produce advanced conductive prints and smart textiles, opening doors to innovative, high-tech applications.

Dirk Tunney, Managing Director of etv, emphasizes the importance of this investment for the company’s future growth: “These investments are hugely important for our business. We expect noticeable new business from the second half of 2025.”

Located in the Münsterland region of Germany, etv operates with around 120 employees, specializing in surface finishing for a variety of textile producers across Europe. Known for its commitment to innovation and sustainability, etv places a strong emphasis on close collaboration with its customers to deliver tailored, high-quality products. This latest investment reflects the company’s dedication to meeting evolving market demands through cutting-edge technology and innovative solutions.