#Dyeing, Drying, Finishing

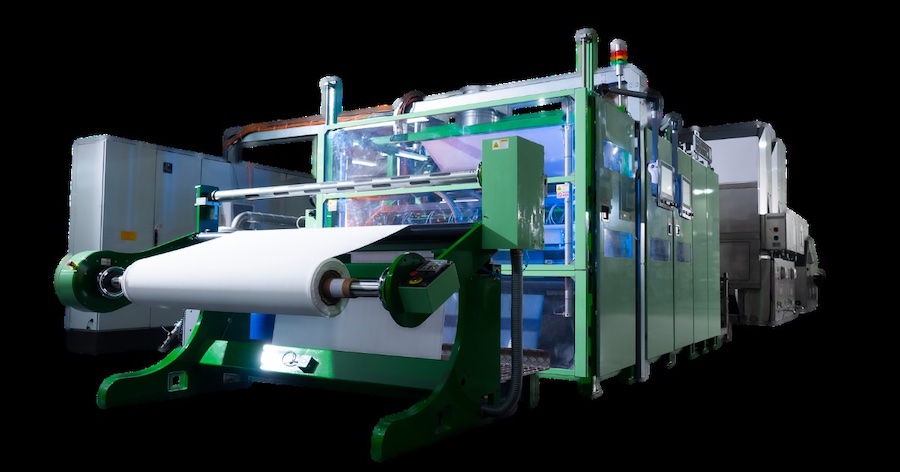

JigMaster – most gentle and versatile

Benninger’s high-tech jigger is the perfect choice for demanding dyers

JigMaster shows cutting-edge technology meeting the demands of modern textile manufacturing. The system, developed in Switzerland and produced in Benninger's state-of-the-art facility in Pune, India, represents a significant advancement in fabric dyeing machinery – just perfect for companies like Swisstulle requiring machinery for highest standards of precision, quality, and sustainability.

A perfect fit to Swisstulle's high standards

Swisstulle (www.swisstulle.ch), a leader in the European market for traditional bobbinet tulle and technical knitted fabrics, decided for JigMaster to improve its textile dyeing and finishing processes. This strategic choice aimed for further enhancement of the company's production capabilities, particularly in washing and dyeing of high-quality technical textiles. Counting over a hundred years of experience, Swisstulle continues to pioneer innovation, ensuring the highest quality and sustainability in its offerings.

Swisstulle supplies its renowned bobbinet tulle and technical textiles to industry segments ranging from fashion to automotive. JigMaster plays a crucial role in supporting their production goals in the area of technical textiles used for sun protection and other high-demand applications.

“Benninger JigMaster provides Swisstulle with a new level of efficiency and sustainability, perfectly aligned with our commitment to resource-conscious production,” says Achim Brugger, CEO at Swisstulle. By integrating the JigMaster into its production line, Swisstulle ensures that its fabrics not only meet but exceed customer expectations, while also advancing its environmental responsibility. The machine’s plug & play capability allows for quick setup and seamless integration into existing production workflows, minimizing downtime and maximizing productivity.

Revolutionizing textile dyeing

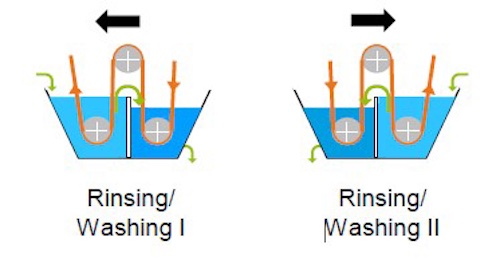

One of the standout features of Benninger JigMaster is its TwinJig technology, which includes two independent troughs, enabling Swisstulle to save up to 35% water during rinsing. This technology also optimizes energy usage, making the dyeing process more eco-friendly without compromising on fabric quality. The machine’s counterflow rinsing and high mechanical washing effect further enhance resource savings by reducing water and steam consumption. These are significant advantages given the textile industry's growing focus on sustainability.

Moreover, JigMaster offers fast heating gradients, enabled by two high-capacity heat exchangers, speeding up production while maintaining superior fabric care. Its BEN-CONTROL software guarantees precise speed and tension control, essential for Swisstulle’s fine fabrics, which require low-tension dyeing to avoid creases or edge marks. Additionally, the machine features precise length measuring and sampling point detection, ensuring consistent quality throughout the production process.

A future-proof partnership

The partnership between Swisstulle and Benninger is a testament to both companies' shared commitment to innovation and sustainability. “With the installation of JigMaster, we strengthen our position as a forward-thinking textile manufacturer. We use the most sophisticated tools to produce high-performance fabrics efficiently and ecologically,” says Brugger.