#Dyeing, Drying, Finishing

Third Monforts Thermex for Turkey’s Altoteks

With an annual dyeing and printing capacity of 18 million metres, the company’s plant already houses two existing Monfortex ranges, along with a Montex finishing range and related equipment.

Exacting standards

The key fields of specialisation for Altoteks include the dyeing and finishing of para and meta-aramid fibre fabrics and blends, unique double dyeing and printing techniques for polycotton and nylon and cotton blended fabrics and special processes for ripstop camouflage materials. Another major field is in the coloration of modacrylic fabrics and flame-retardant cotton and viscose blends. All must meet the exacting standards of the military and civil defence services.

“Specialised equipment and know-how are required to achieve the high durability, colour fastness and performance standards required on the woven fabrics for the markets we serve and Monforts Thermex technology is one of the cornerstones of our expertise,” says owner of the company Mehmet Ucar. “We use the Thermex ranges for continuous, disperse and reactive dyeing processes and they are generally preferred for technical textiles and long-run reactive dyeing.”

“With its technologically advanced infrastructure, experienced staff and environmentally friendly production, Altoteks is constantly increasing its domestic and international competitiveness, with customers in Europe, Asia, the USA and Africa,” adds Monforts Area Sales Manager Thomas Päffgen. “Having embraced quality, sustainability and customer satisfaction as its core principles, Altoteks is thriving in some highly specialised markets.”

Econtrol®

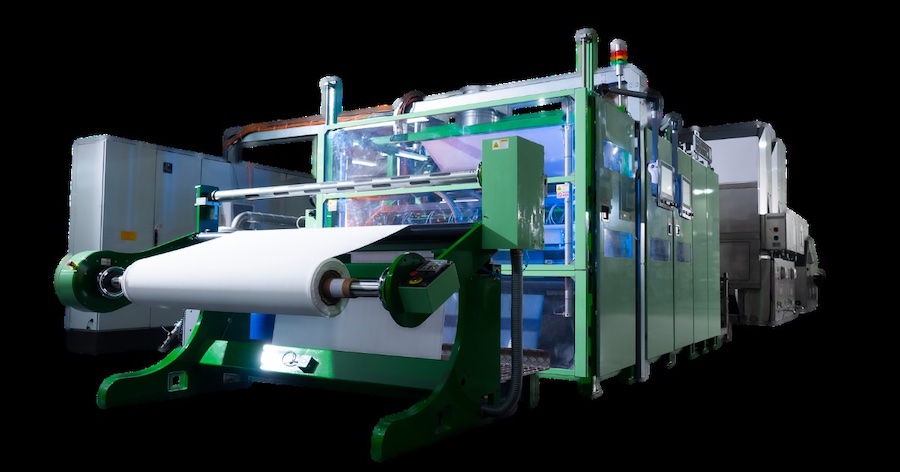

The new two-metre-wide Thermex line consists of three linked Thermex units for continuous dyeing and thermosoling, along with gas-powered infrared predryers, providing high evaporation rates in a minimum of space, and cold pad batch (CPB) winding.

With the trend towards smaller lot sizes per colour in continuous dyeing and the requirement for simple processes, the new Altoteks range also benefits from the Econtrol®* process for reactive dyestuffs developed by Monforts together with Dystar – a simple, quick and economical one-pass pad-dry-wash off continuous dyeing process with drying in the hot flue at 120-130°C and controlled humidity of 25-30% by volume, to obtain fixation in two-to-three minutes.

“The Econtrol process provides a significant advantage for our company, allowing for faster and more economical production in high-volume reactive dyeing,” says Mehmet Ucar “For Altoteks, the new machine will significantly improve production processes in terms of speed, quality and operational efficiency.

“The installation process was completed in a record time of approximately one month with the support of Monforts, its local agent Neotek and our technical team. Monforts consistently provided us with the necessary service support once the machine began production.”

*Econtrol® is a registered trademark of DyStar Colours Distribution GmbH, Germany.