#ITMA Asia + CITME 2022

Sedo Treepoint at ITMA ASIA + CITME 2022: Sustainability and performance for the textile industry

Together with their partner Smart Indigo, Sedo Treepoint combines both topics at its booth in hall 5 booth C25 in Shanghai and will be presenting its innovative solutions from November 19 - 23, 2023, which help to unite sustainability and performance. For example, the automation specialist will be showing the Sedomat 8000 and 6007 series in interaction with the latest innovative jet and yarn software as well as software innovations ColorMasterConnect and TEXconnect to save money and resources.

Whether as a strategic solution for current Industry 4.0 requirements or due to its great flexibility for future standards: Sedo Treepoint, as a leading supplier of integrated automation systems for the textile dyeing and finishing industry, provides users with a comprehensive range of solutions for machines and software solutions in this industry. The automation specialist will be presenting a highly exciting selection at the 8th ITMA ASIA + CITME 2022 textile trade fair. At the joint booth of Sedo Treepoint and partner Smart Indigo from November 19 - 23, 2023, trade visitors will have the opportunity to see the controllers and systems on display and experience the combination of greater sustainability and performance in an ever-evolving industry.

Some of the highlights are the latest control systems of the Sedomat 8000 and 6007 series and newest software solutions, which show innovative application possibilities for Industry 4.0. In addition to the latest innovative jet and yarn software, visitors will also learn how they can increase their level of automation with the ColorMasterConnect or TEXconnect software solutions and how the controls can bring their application to the highest standard and thus boost their productions to a new level.

Most advanced machine control

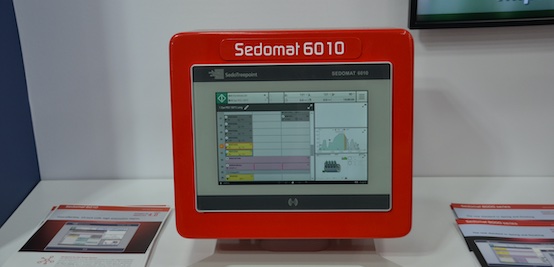

To ensure that the latest requirements of Industry 4.0 can be used safely and reliable and that high product quality is achieved in the end, it is important that the application is always highly flexible and consistently stable in its performance. The new Sedomat 8000 series was developed for such smart factory applications and has all the advantages of the established Sedomat controllers.

With internal Wi-Fi, RFID, flexible fieldbuses and a large number of internal and external inputs and outputs, it offers a wide range of connectivity options as well as advanced options that can be connected more efficiently than ever before and maximize flexibility in software selection. The powerful controller thus offers an impressive user experience and hardware at the highest level. With these advantages, the new generation of controls is also suitable for use in rough production environments and meets maximum quality standards with maximum convenience.

The focus of the control series will also be on the latest member of the Sedomat 6007 series: The Sedomat 6007 series is a cost-effective option with a high level of automation that offers many flexible internal I/O options. For example, an integrated PLC is already included in the attractive alternative. A wide variety of requirements from yarn, piece and other dyeing machines can additionally be realized via optional internal and external in- and outputs. The integration of SedoMaster and other dyeing systems using e.g. Ethernet, OPC UA and MQTT also ensures sustainable and competitive production, which optionally also supports RFID and is therefore suitable for data acquisition or as a production terminal. Altogether, the Sedomat 6007 series offers users a cost-effective control solution that provides the highest quality and reliability to meet all requirements in Industry 4.0.

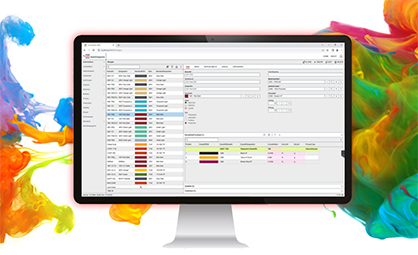

Increased level of automation with new software systems

In addition to the latest controllers, visitors will also experience how they can increase their level of system integration with innovative software of two new software systems: TEXconnect, as a cloud-based platform for the textile industry is easy to set up and offers the most common functions of the on-site "master" systems at a low investment cost. In addition, ColorMasterConnect, as a web-based color management software, allows users to use it on any device and on different operating systems. With these new tools, customers can bring their application to the highest standard, taking their production to a new level by optimizing their recipes and saving costs and resources.

Trade visitors will find Sedo Treepoint at ITMA ASIA + CITME 2022 in Shanghai in hall 5 at booth C25.