#Industry 4.0 / Digitalization

BMSvision celebrates 50 years of innovation in Manufacturing Execution Systems

Half a century of empowering productivity in the textiles and plastics industry

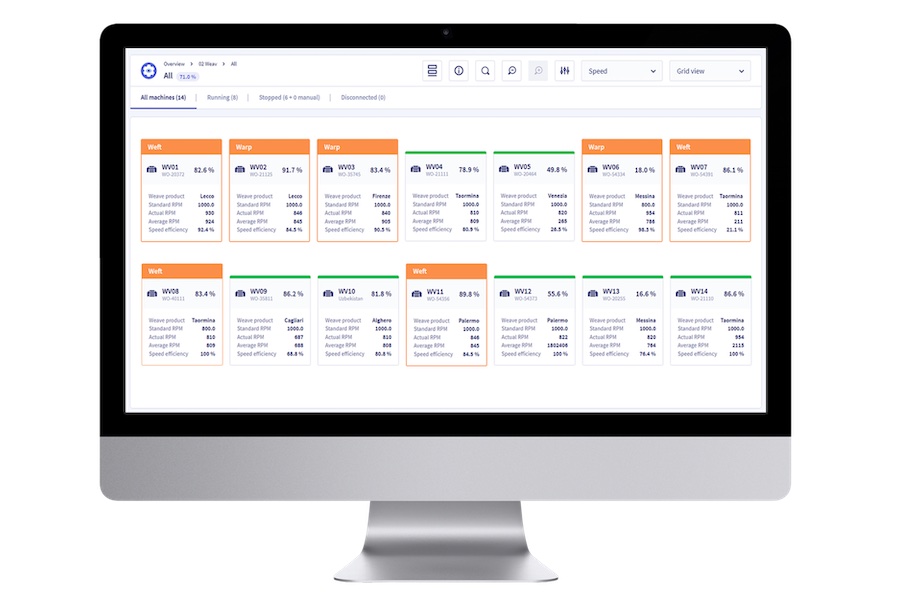

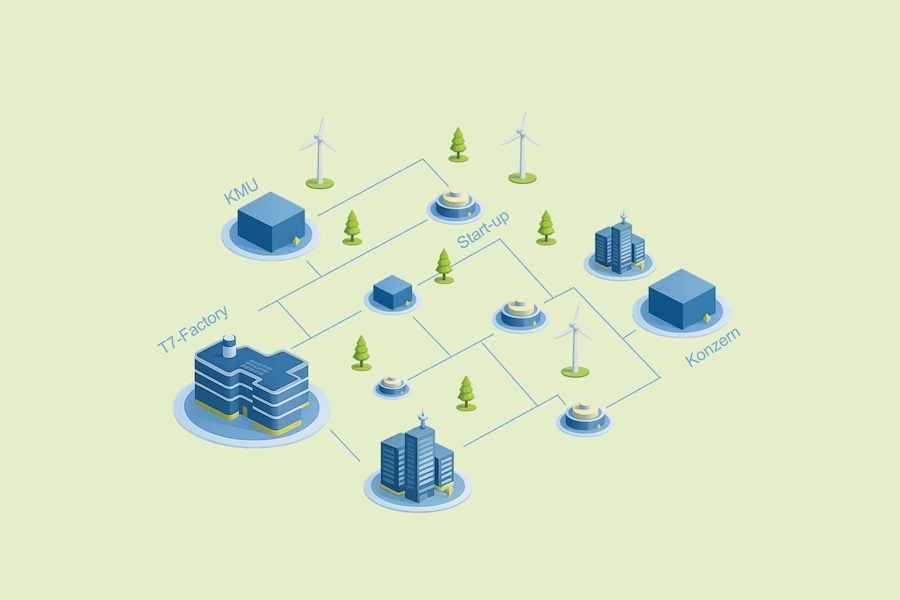

Since its debut in 1975 as part of the Barco Group, BMSvision has evolved into a trusted partner for the discrete manufacturing industry worldwide, streamlining production, improving efficiency, reducing waste, and making smarter, data-driven decisions based on real-time information. From pioneering digital manufacturing in textiles to delivering advanced MES solutions tailored to today’s industrial needs, BMSvision continues to lead the way in smart manufacturing.

“Reaching this 50-year milestone is more than a celebration of our past – it’s a testament to the partnerships we’ve built, the industries we’ve helped transform, and the people who’ve shaped our journey,” says Jan Bogaert, CEO of BMSvision. “As part of the Vandewiele Group, we remain committed to driving operational efficiency and empowering productivity for decades to come.”

Charles Beauduin, President Vandewiele Group, adds to this: “Vandewiele has been focussing on technical innovation for years. Continuing to invest in product development and digital transformation is the key to the future. BMSvision plays a crucial role within the group to achieve these technological ambitions.”

Today, BMSvision’s MES solutions are deployed in factories across the globe, offering real-time data insights and seamless integration from shop floor to top floor. With a focus on textiles, packaging and plastics, BMSvision continues to combine in-depth industry domain knowledge and state-of-the-art technology expertise with a relentless focus on customer success.

As BMSvision marks this significant anniversary, the company looks ahead with a clear mission: to continue innovating, integrating, and delivering solutions that manufacturers can rely on, today and tomorrow.