#Nonwoven machines

Dilo Systems and Kansan Group partnership announcement

As part of this partnership, comprehensive solutions will be offered by integrating fiber preparation and carding equipment, wetlaid, hydroentanglement and needling lines, as well as converting and end-of-line equipment. Engineering work will be carried out by Dilo Systems GmbH as the main contractor.

This collaboration primarily focuses on specialized nonwoven markets, particularly for hygiene, medical, and technical applications. The production of specialized nonwovens consisting of short and long staple fiber layers is the goal. These nonwovens are typically made from cellulose pulp and carded materials. In hygiene and medical applications, short-cut cellulose materials play a critical role in absorbing and retaining liquids. When the fiber length drops below 12 mm, the faster flushability of cellulose material offers a significant advantage in terms of waste management.

Wetlaid pulp can be hydrodynamically shaped using headbox technology (flowlip, inclined wire), which can be designed according to demand.

Wetlaid products can be further processed with carded web layers and hydroentanglement, integrating into different production processes.

Kansan Materials has successfully established a production line capable of processing hybrid raw materials developed based on the latest hydrodynamic simulation calculations. This line is equipped with advanced software technologies that assist operators in managing production processes in a fully automated, computer-supported mode.

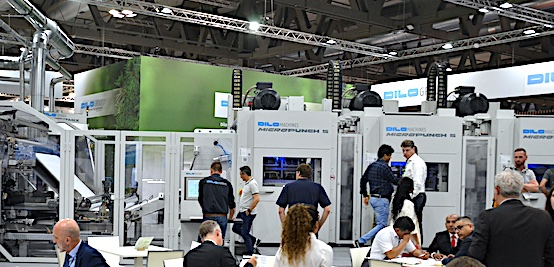

As the main contractor, Dilo Systems GmbH aims to enhance the efficiency of nonwoven production for the hygiene and medical sectors by integrating Kansan’s wet wipe converting lines and end-of-line equipment. In this scope, the integration of materials produced with Dilo’s “CycloPunch” and “MicroPunch” needling machines into Kansan’s wet wipe converting lines is planned. Kansan is a strong partner in this field, with its expertise and leading position in the industry.

This joint development process and marketing efforts lay an excellent foundation for offering complete lines that can produce carded and needle-punched, carded and hydroentangled, carded and wetlaid nonwovens, as well as combinations of these techniques.

With a vision of offering innovative and sustainable solutions in the nonwoven sector, this partnership aims to increase production efficiency while minimizing environmental impact. Dilo Systems GmbH and Kansan’s technical expertise provides faster, cost-effective production processes tailored to customer needs. Furthermore, solutions have been developed in line with sustainability goals, such as energy efficiency and the use of recyclable materials. This collaboration is designed to create new opportunities in global markets, particularly in the hygiene, medical, and technical sectors, while expanding our reach to a broader customer base.