#Raw Materials

Kraig Biocraft Laboratories unveils groundbreaking scientific achievement based on caddisfly silk proteins

Caddisflies (known in the Pacific Northwest as “Periwinkles”) are known for their extraordinary ability to spin silk underwater, which they use to construct protective cases in aquatic environments. By leveraging the unique mechanical and chemical attributes of caddisfly silk proteins, Kraig Labs seeks to engineer materials with unprecedented functionality. This new silk offers the potential for increased durability when submerged in water. Possible applications for this new silk are vast, with exciting potentials for medical adhesives, biomedical textiles, performance apparel, and next-generation fiber technologies.

“This achievement demonstrates our ability to extend beyond spider silk proteins and explore the broader possibilities of silk engineering,” said CEO and Founder of Kraig Labs, Kim Thompson. “By tapping into the evolutionary diversity of silk-producing organisms, we’re expanding the toolkit for creating super fibers that meet the demands of tomorrow’s industries.”

The introduction of caddisfly-based transgenic fiber represents a critical milestone in the Company’s vision to create new super materials blending the physical and chemical properties of various silk proteins. The result is an ever-growing portfolio of high-performance materials designed to redefine the standards of strength, elasticity, and functionality. These new fibers will leverage the Company’s propriety silkworm-based production system to bring these materials to market.

“Incorporating the unique and incredible adhesive properties of caddisfly silk protein has been a key part of the R&D roadmap I laid out when founding Kraig Labs,” Thompson continued. “Unveiling this pivotal scientific milestone, our first caddisfly-based transgenic, marks not only a significant leap forward for the Company’s business model but also a deeply gratifying achievement for me personally and for our team.”

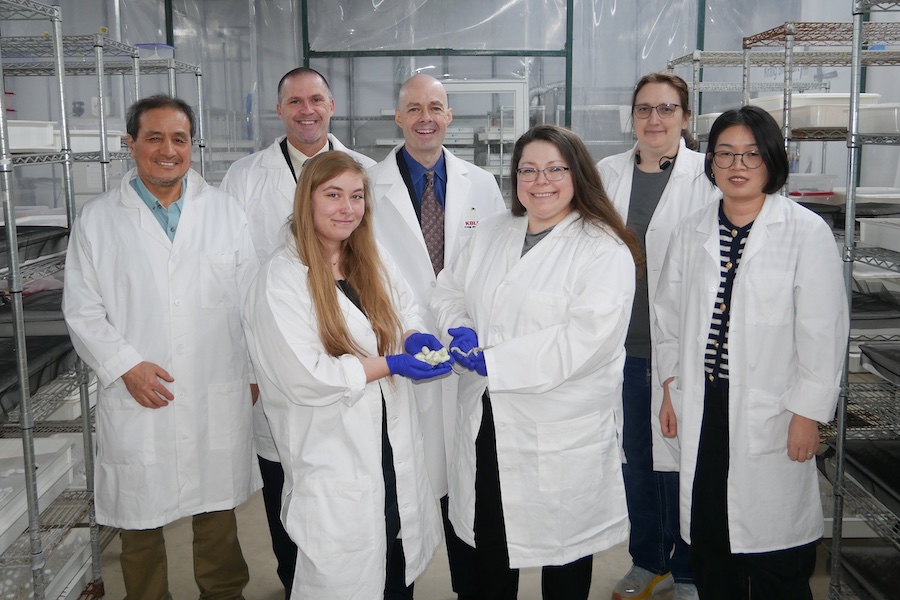

This breakthrough would not have been possible without the dedication and ingenuity of the Company’s scientific team. Their relentless pursuit of excellence and creative problem-solving have once again positioned Kraig Labs at the forefront of biotechnological innovation.

“Our team’s success with this caddisfly-inspired material is a testament to the power of combining cutting-edge science with bold vision,” added the Company’s COO, Jon Rice. “We are excited about the potential this fiber holds and the new opportunities it creates across multiple sectors.”

Kraig Labs is committed to pushing the boundaries of creativity and science in silk protein engineering. The Company has filed a provisional utility patent application for this exciting new technology. By exploring and integrating the diverse properties of silk from various species, the Company will continue to lead the charge in developing sustainable, high-performance materials that address real-world challenges.