#Textiles & Apparel / Garment

SAITEX releases 2024 impact report, showing decarbonization at scale and industry-leading circularity

The Vietnam and U.S. based apparel manufacturer reports double-digit production growth while reducing emissions per garment by 18% and scaling renewable energy, water recycling, circularity and social stewardship programs.

Even though production grew by 25% in their apparel manufacturing division and grew by 124% at their denim mill, the company cut carbon emissions by 18% and 16% respectively. They also advanced existing closed-loop water systems and expanded social and circularity programs, demonstrating what clean fashion manufacturing can look like in the 21st century.

“Our mission has never been about incremental change, but about systemic transformation,” said Sanjeev Bahl, Founder and CEO of SAITEX. “Our 2024 results exhibit that scale and sustainability are not in conflict. We’ve demonstrated growth can align with measurable reductions in carbon, water, and waste. As a vertically integrated ecosystem, we’re committed to sharing both our successes and shortcomings transparently.

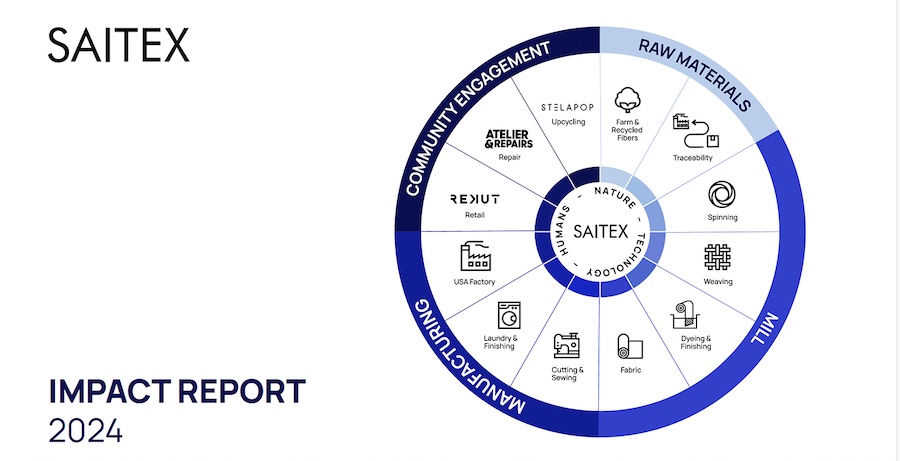

Since its inception in 2001, SAITEX, regarded as the ‘cleanest denim factory in the world’, has been grounded in purpose and driven by a mission to improve social and environmental practices in the apparel manufacturing space. Over the years, the organization has organically evolved from an apparel manufacturer into an ecosystem which currently includes: Saitex Apparel Manufacturing in Vietnam (2006) & USA (2021), Saitex Fabric Mill with its own spinning in Vietnam (2022), STELAPOP upcycling (2019), REKUT (2019), and Atelier & Repairs (2021). All of these entities share the same vision and work jointly to redefine the way we make and [re]use denim.

Key 2024 Impact Report Highlights

(SAITEX reports with full transparency on areas requiring continued focus)

Apparel Manufacturing (Vietnam)

Production & Energy: Production output increased 25% Year over Year, with electricity use per garment went down by 6,8% while emissions per garment decreased by 18% (5,56 ? 4,56 kg CO?e per garment).

Carbon Offsetting: In 2024, 8647 trees were planted through a partnership with Gaia Nature Conservation program, contributing to a cumulative target of 139 783 trees by 2027. Combined with solar expansion, this supported a 35% CO? offset in 2024. Furthermore the Gaia partnership also advances biodiversity, soil health, and community livelihoods.

Steam & Gas: Steam per garment down by 26,8%; gas use up by 16% due to 3D fashion and coating processes demand. Mitigation planned via switch from MPG to solar powered operations as rollout expands.

Water & Wastewater: Water use per garment up by 7,3% and wastewater discharge up by 21,4%, linked to scheduled RO filter replacement (June 2025). Laundry remains closed-loop since 2016, recycling 98% of water.

Waste & Circularity: Waste increased by 1,1% due to new chemistry testing. Fixes include repurposing 40% of sludge into bricks/blocks and scaling STELAPOP’s NFC-powered upcycling program.

Denim Mill (Vietnam)

Production & Energy: Production output increased by 124%, with electricity use per meter down by 16% and emissions per meter down by 18% (4,04 ? 3,31 kg CO?e per meter).

Energy Mix: Achieved 70% renewable energy (34% onsite solar, rest coming from industrial park).

Water: The Mill is preparing to install a closed-loop wastewater system by Nov 2025, aiming for minimal freshwater input.

Waste: Waste dropped by 8%, with 92% of being recycled.

Certification: Mill became a bluesign® System Partner (Nov 2024) where 18% of fabrics are bluesign® certified fabrics allowing for seamless integration into already certified bluesign® apparel manufacturing. Thanks to this, brands have an opportunity to produce fully certified bluesign® garments.

Human & Community Impact (Across all operations)

Community Outreach: Programs expanded by 60%, reaching 13 245 people through Every Drop Counts (launched 2019), 4Ps (2005), Clean Water Project (2024), and other education initiatives.

Workforce Inclusion: REKUT program continues to integrate disabled workers into core production lines.

Community Impact: Introduced Gaia x Saitex employee initiative called Transforming Used Items to Trees Gaia Project.

Traceability & Data

LCAs: Ongoing Life Cycle Assessments since 2019. In 2024, mill LCAs migrated to Made2Flow for more granular data assessments. Garment LCAs will be consolidated in Q1 2025 put under the same umbrella due to contractual agreements.

Digital Product Passports: Rolled out for brand partners in 2023, providing higher transparency and compliance readiness.

Areas for Improvement & Next Steps:

Gas Usage (increased 16%): Driven by higher energy needs of 3D processes; addressed through process optimization, electrification and designer education. Planned to switch from LPG powered operation to solar powered with future solar expansion.

Water & Wastewater (increased by 7,29% / increased by 21,4%): Temporary increases tied to reverse osmosis filter maintenance; updated system fix scheduled for June 2025.

Waste (increased by 1,1%): Increase linked to expanded chemistry testing; mitigation includes reuse initiatives and scaling up STELAPOP.

Labor Practices: Internal audit flagged 27 cases of undeclared Sunday work. Fixes implemented and improved by digital overtime tracking, worker retraining, quarterly compliance audits, and updated bonus systems. All workers have been fully compensated.

Forward-Looking Goals

Apparel Manufacturing (Vietnam): 100% renewable energy by 2027; with progress towards 35% on-site solar by end of 2026.

Denim Mill (Vietnam): Closed-loop wastewater with minimal fresh water input by end of 2025; aiming for net-zero operations by 2030.

System-wide: Expansion of circular STELAPOP materials, using NFC-powered trims, and carbon-positive ambitions.