#Yarn & Fiber

Successfully passes Nadcap audit: Certification confirms highest standards in aerospace quality

Nadcap is the leading international program for auditing and accrediting special processes in the aerospace and defense industries. Managed by the Performance Review Institute (PRI), the audit applies demanding requirements in terms of process control, quality assurance, and documentation.

“This achievement marks an important milestone for our company and underscores our commitment to technical excellence and the highest quality standards,” says Jana Kubitz, Head of Aerospace Marketing, EMEA. “For our customers, Nadcap accreditation is a strong signal of our reliability and precision – especially for safety-critical applications.”

With this successful Nadcap certification, Teijin Carbon strengthens its position as a trusted partner for highly demanding industries worldwide. The accreditation not only enhances our competitiveness but also opens up access to new markets and customer segments – particularly in the aerospace sector.

Teijin Carbon

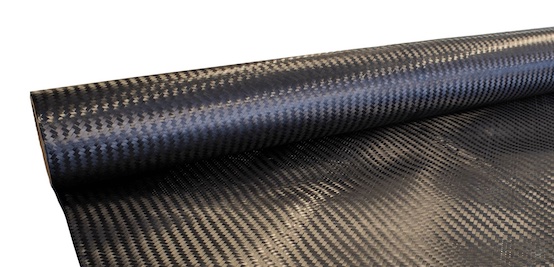

Teijin Carbon is a subsidiary of the Teijin Group, specialized in the production and development of carbon fibers and carbon fiber-based materials. Under the carbon fiber brands Tenax™ and Tenax Next™, Teijin Carbon offers high-performance material solutions for industries such as aerospace, automotive, energy, electronics, civil engineering and sporting goods.

Teijin’s carbon fibers enable the creation of lightweight yet incredibly strong components – about a quarter of the weight of steel while offering ten times the strength. They also excel in fatigue resistance, corrosion resistance, and chemical stability, making them ideal for a wide range of applications.

Teijin Carbon has production facilities in Japan, the United States, Germany, Vietnam and sales offices all around the world. For further information please visit: www.teijincarbon.com.