#Associations

Promoting sustainability, digitalisation and resilience

The ADDTEX project brings together partners from a total of twelve European countries. The IVGT, Frankfurt is a partner for Germany and represents the interests of its members and the entire technical textiles sector. The aim of the project is to sustainably promote close co-operation between industry, science, politics and civil society. This innovative approach, known as the ‘quadruple helix model’, is intended to help prepare the industry for the challenges of a volatile, uncertain, complex and ambiguous environment (VUCA), which have been exacerbated by crises such as the COVID-19 pandemic. ‘By focusing on green technologies, digitalisation and continuous training, we are making the technical textiles industry fit for the future,’ says Stefan Schmidt, IVGT project manager. ‘We want to strengthen the competitiveness and sustainability of this important sector.’

Workshops as a basis for policy recommendations

Between September and October 2024, the ADDTEX partners organised interactive workshops in Germany, Greece, Italy and Spain. These served as a platform for a broad dialogue between industry, science and politics, in which innovative approaches and concrete strategies for action were developed. The participants focussed on topics such as sustainable practices, digital transformation and promoting resilience in the textile industry.

Key competences for change

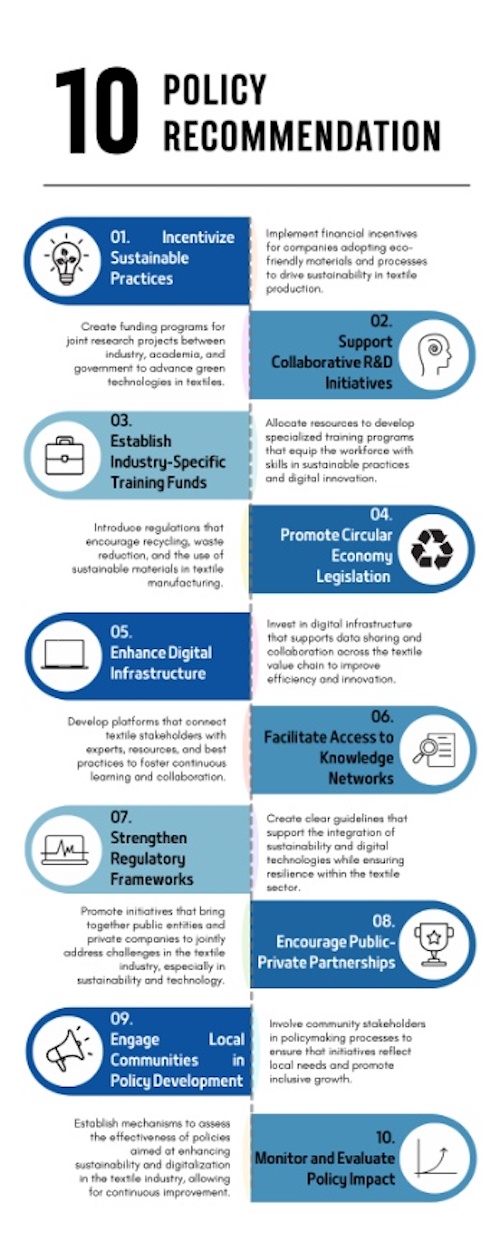

A central aspect of the White Book is the emphasis on education and training to promote the dual transition - green and digital. The most important skills required of employees to shape a sustainable future for the industry are expertise in renewable energy, recycling, environmentally friendly materials and sustainable production (green transition), skills in data analysis, cyber security, IT and the ability to use AI-supported technologies (digital transition), as well as adaptability, innovation, risk management and cross-functional collaboration (promoting resilience). Ten aspects emerged as the most important political recommendations for action (see chart). These include, in particular, the promotion of sustainable practices in companies, investment in digital infrastructure along the textile value chain, support for collaborative research projects and industry-specific training funds to impart the essential skills mentioned.

Further information www.addtex.eu; www.addtex.eu/resources/