#Dyeing, Drying, Finishing

First division knitters in Europe and Asia choose the Monforts MONTEX

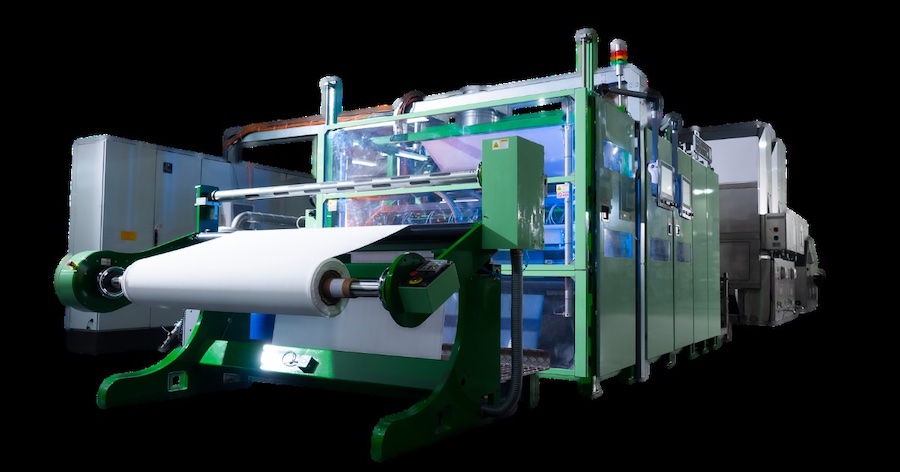

“Knitted fabrics need delicate handling as they often have a higher degree of elasticity compared to more rigid woven materials,” explains Monforts Marketing Manager Nicole Croonenbroek. “Our MONTEX stenters provide smooth treatment at very low and precisely controlled tension during all stages of knitted fabric handling, as well as very gentle and even thermal treatment. The MONTEX is extremely flexible in terms of the different fabric qualities it can accommodate and also provides significant benefits in terms of energy consumption.”

Europe’s leader in dyeing and finishing

As one of the largest dyers in Europe, ATB – Acabamentos Têxteis de Barcelos – founded by Mário Mano in 1985 in Barcelos in northern Portugal, is dyeing and finishing between 36-40 tons of fabric on a daily basis for key customers including Benetton, Inditex and Mango.

ATB installed its first Monforts MONTEX stenter frame in 1990 and has subsequently ordered four more over the years. All are 2.8 metres wide and use heat recovery units for increased energy efficiency and also the latest control equipment, to grant the highest possible process quality/reproducibility. In addition, the ATB plant is equipped with two Monforts Dynair relaxation dryers and one EcoApplicator.

Knitting is carried out at Etevimol, also in Barcelos, which during 2024 became 100% owned by the Mano family. Etevimol’s 160 knitting machines are now being transferred to the ATB plant and a €5 million investment is planned in new knitting machines.

ATB also holds some 10,000 fabric samples in stock, and its library is constantly growing.

“Our customers will ask for initial fabric samples and then very quickly need five metres of the fabric for prototyping, so we have to be very organised in this respect,” says Mário Mano’s son and company CEO Ricardo. “We also do a lot of shopping to equip our showroom, in order to investigate how our fabrics turn out in finished garments, and to let our visiting customers know that we are anticipating all of their needs – with the help, of course, of our leading technology suppliers like Monforts.”

Interloop’s ambitious expansion

Another major Monforts customer is Interloop, a company which started humbly in 1992 with just ten knitting machines for hosiery production and has grown into the one of Pakistan’s largest publicly listed textile firms

Interloop is aiming to achieve $700 million in annual sales in 2026 following its latest ambitious expansion programme and key customers include Adidas, H&M, Nike and Target among many other well-known brands.

The company’s latest fully-integrated knitwear plant in Faisalabad, Pakistan, is being equipped to produce fifty tons of knitted and dyed fabrics on a daily basis, for the production of 45 million finished garments annually.

The 1.25 million-square-foot facility is Interloop’s most technologically advanced to date and has earned the highest LEED score for a facility of its scale. It is powered extensively by renewable energy, including biomass boilers, and is supported by advanced water management and effluent treatment systems.

“We’re setting new standards by harnessing innovative technologies and relentlessly pursuing process improvement,” says Navid Fazil, Interloop CEO. “Through our LEED certified infrastructure, a self-reliant,green energy grid and transition to biomass fuel, we’re committed to increasing Interloop’s sustainability impact on an unprecedented scale.”

Reliability

“Monforts MONTEX stenters are the industry standard for the fabric finishing industry, and offer knitwear manufacturers a number of advantages in terms of sensitive handling and precise control, production throughput and energy efficiency and savings,” concludes Nicole Croonenbroek. “Our machines remain unmatched in terms of their robustness and long service life and are reinforced by our commitment to customer service based on four principles – being helpful, accurate, fast and reliable.”