#Dyeing, Drying, Finishing

NTB’s unique Monforts MONTEX business gets a full upgrade

Twenty years later, by 2019, the company had grown to a 40-strong workforce operating three MONTEX lines at two adjacent plants covering over 3,500 square metres. NTB sales that year exceeded €8 million for the first time.

Forward momentum

NTB’s initial focus was on the coating of mainly glass fibre fabrics and awnings and sun protection products for outdoor furnishings, as well as breathable membrane film laminations for sportswear.

“We had a great customer who was providing us with so many orders that by 2005 we took the decision to order a second MONTEX stenter, in a special configuration,” explains managing director and founder Rainer Hurtz. “This also allowed us to enter the market for blackout and digital printing fabrics.”

Another important development for the company was its approval by the German Armed Forces (Bundeswehr) for the supply of vector protection clothing and equipment. NTB’s special finishing technology is essential in shielding military personnel from insect bites and vector-borne diseases which can be prevalent and deadly in many areas of the world. In 2023, Germany’s Ministry of Defence subsequently granted NTB an exemption for the processing of permethrin for its vector protection services, in the interest of national defence.

Covid-19 resilience

In 2015, a third MONTEX production line with a working width of 3.4 metres was installed to meet ever-increasing demand, but inevitably, the company’s forward momentum was set back somewhat as a result of the Covid-19 pandemic.

Despite a sudden 70% drop in sales, NTB was nevertheless able to retain all its staff and in 2020 founded Gorilla Protect GmbH, as a distributor of advanced anti-viral face masks.

Post-pandemic, regular business has resumed and the company celebrated its 25th anniversary in 2024.

It is now in the process of a generational change, with Rainer Hurtz stepping back and management of the company being transferred to his son Oliver as Commercial Director, along with Technical Director Bastian Schreurs and Sales and Development Manager Lampros Kampas.

“I will accompany and support them as long as it makes sense,” says Rainer Hurtz. “The company’s goal has always been to understand how processes work and to continuously optimise them. As such, our current focus is on process data acquisition and analysis, a high degree of digitalization, actively implemented quality management and the introduction of an energy and occupational safety management system. If you stop getting better, you’ve stopped being good.”

Digital affinity

Technical Director Bastian Schreurs – who was NTB’s first-ever trainee – has worked closely with Monforts specialists on the modernisation project and is in full agreement.

“Our goal is to be able to offer a high level of quality and service, with our business under constant price pressure from our Asian competitors,” he says. “We see this modernisation project as an opportunity to further establish ourselves and thus retain our customers. It is also important to continue advancing our digitalization, firstly, to better understand our processes, and secondly, to remain attractive as an employer. Young people have a strong affinity for digital things and while we can always buy the best machines, without well-trained specialists to operate them, it’s impossible.”

He adds that the electronic controls of the two older MONTEX stenters particularly needed updating, as sourcing spare parts, most notably of the frequency converters, had become increasingly difficult.

Updated system

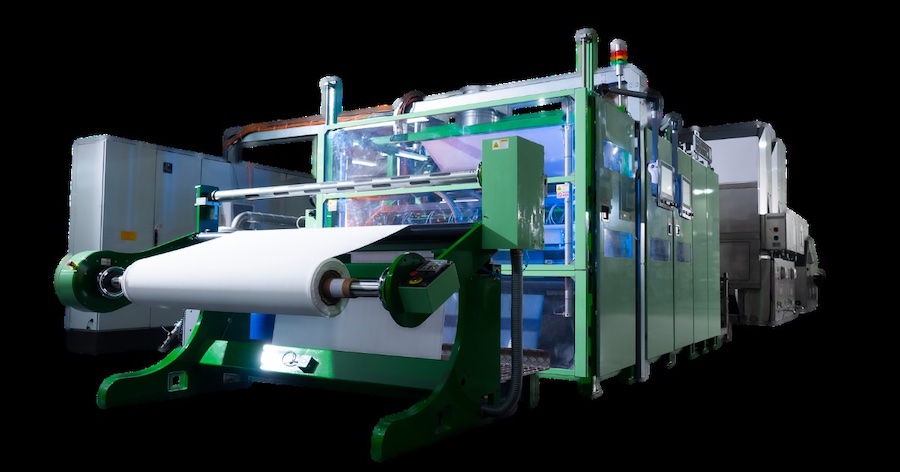

Monforts has subsequently installed new control cabinets and Qualitex 800 technology to the two older MONTEX stenters at NTB, along with programmable logic controller (PLCs) process visualisation and 24-inch TFT multi-touch colour screens at the stenter frame infeeds.

The outfeed, padder and calender have further been equipped with seven-inch touchscreen control panels and all frequency inverters for the drives used to transport the textiles have been updated.

Overall control is via a Siemens TIA 1500er F portal and a Gateway server/client OPC/UA interface.

“The clamping frames of the stenters are now equipped with the latest drive and control technology as well as visualisation and thanks to the OPC-UA interface, data can now be read out directly from the PLC and analysed by a customer’s EAP system,” explains Monforts Area Sales Manager Thomas Päffgen. “Our machines are known for their robustness and long service life, but the retrofitting of specific modules with new control and drive technology – going far beyond the basic replacement of spare parts – can have a significant impact on the performance of an existing line.”

Quality

“Our goal was to be able to produce all fabric orders on any of the three MONTEX lines, and we naturally chose Monforts for this project,” adds Bastian Schreurs. “We didn’t have to do anything mechanically apart from updating the safety devices, which speaks volumes about the quality that Monforts has been delivering to us for 26 years now. I would like to once again praise the Monforts service department headed by Volker Gingter and our own workshop staff, because not only the scheduling, but also the implementation of this project was virtually seamless. It is very important for us to have competent and always available partners and unfortunately, as we have repeatedly experienced, this is not a given these days.”

“We’ve had a great ongoing relationship with Monforts from the beginning,” concludes Rainer Hurtz.