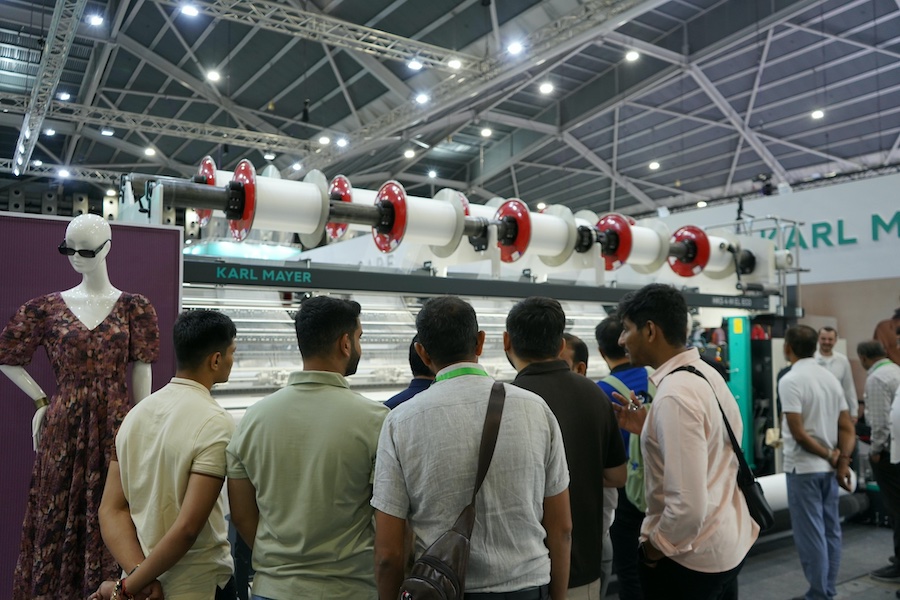

#ITMA Asia + CITME Singapore 2025

Swiss company showcases new technologies for lowering water and energy consumption

The textile industry continues to come under pressure, sustainability is becoming a key competitive factor

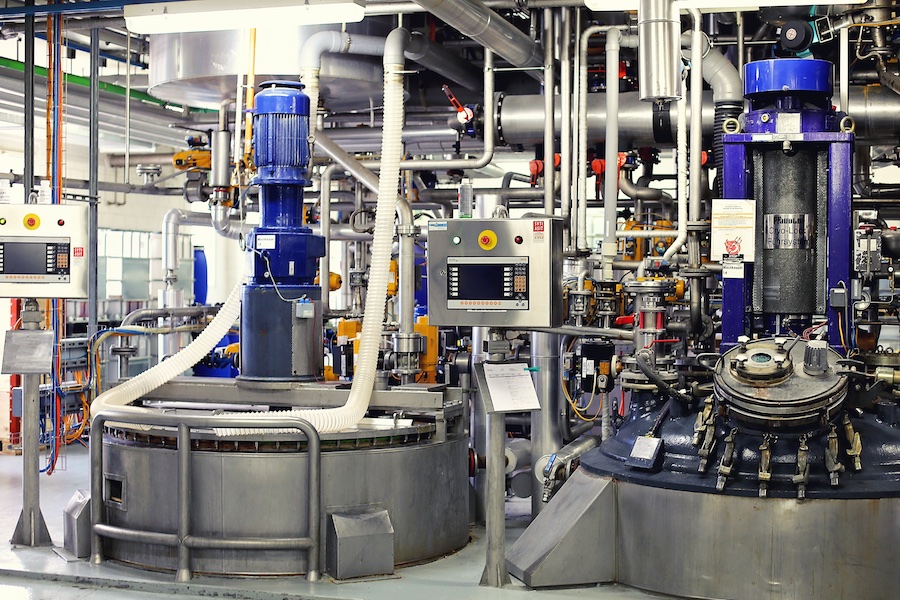

At the trade fair in Singapore, the Swiss company Textilcolor AG is showcasing how textile treatment is still fit for the future. Technologies such as EcoDye and EcoFix enable the company to reduce water consumption by up to 71 %. These processes also allow the amount of fossil-fuel energy used to be reduced by up to half of the previous level across the entire production process. The results achieved speak for themselves. They allow a significant reduction in the carbon footprint and provide an advantage in terms of innovation for an industry currently in the midst of an ecological transformation.

ITMA Asia + CITME 2025 is regarded as one of the leading trade fairs in textile and clothing manufacture in the Asian region. “We have always stood for innovative, sustainable and high-quality solutions in textile chemistry,” explains Detlef Fischer, CEO of Textilcolor AG. “For us, the trade fair in Singapore is the right platform for effectively showcasing our technologies as part of a future-focussed industry”. The slogan for this year's trade fair is ‘ECO Performance Technologies from Switzerland’. Sustainability is firmly established within the corporate philosophy – the company has always developed technologies which lower resource consumption and which continue to reduce the carbon footprint of textile production. One particular focus is on using raw materials from renewable sources. An example of this is the use of plant-based oils in order to conserve fossil resources as much as possible. In many parts of the world, freshwater is in increasingly short supply; companies are having to be ever more focussed on using this element in a sustainable way. The company has also led the market here in the development of water-saving technologies.

Future developments are increasingly focused on sustainable and resource-saving technologies

Under the EcoDye label, a process has been developed which is specifically tailored to the requirements of PES dyeing processes. Textilcolor AG was the first company in the world to successfully launch this product onto the market. The optimisation and enhancement of EcoDye has continued ever since in order to guarantee a sustainable and efficient dyeing technology and to facilitate its ongoing development. It reduces water consumption by up to 71%, and at least 34% less energy is used in the polyester dyeing (PES) process. These resource savings mean it is regarded as one of the most efficient and environmentally-friendly dyeing systems in synthetic textile dyeing, with the smallest carbon footprint. With the EcoDye process, specific work steps can be removed (e.g. prewash), a shorter heating rate means the dyeing process can be accelerated and subsequent treatment processes can be reduced. Use of this method means that, for the customer, the duration of the process is significantly shorter. One specific advantage for users is that the EcoDye process can be used with pre-existing recipes. All EcoDye components are bluesign®-approved. When combined with other technologies from the Swiss company – such as EcoFix and EcoThren, two rapid dyeing processes for reactive and vat dyeing – the reduction in the rinse baths required enables a time-saving of up to 40%. Production output can also be significantly increased, marked reductions in manufacturing costs can then be achieved and product quality can be improved. For safeguarding the entire process and for ensuring optimal dyeing results, Textilcolor has the appropriate products in its range such as levelling and dispersing agents. Other speciality products preventing the agglomeration of oligomers or for reductive after-clearing complete the product range. These products ensure the stability and reliability of the entire dyeing process on an ongoing basis. At the trade fair, Textilcolor AG will also have other proven technologies available such as EcoPhob, a PFC-free hydrophobicity solution. EcoPhob EXT is also an environmentally friendly product with an excellent hydrophobic effect. It is suitable for use generally with all types of fibre and, for example, has excellent washing resistance. The product also consists of the maximum possible proportion of renewable raw materials. It can also be used for manufacturing textiles which meet the requirements for class 1 products under the Öko-Tex standard.

Wide-ranging offer covering the entire textile process chain

Textilcolor AG is not only known for manufacturing all products in accordance with strict ecological and sustainability standards. The continual development of new products and solutions is indicative of the company's leading role in the market. These are frequently tailored to the wide range of processing requirements – often in close collaboration with customers. The broad product range has now become a further feature of the company. In contrast to other suppliers, which generally only offer products for individual processes, Textilcolor covers the entire textile process chain. The broad product range covers all steps from pre-treatment, printing and dyeing, finishing and coating, to pigmentation and optical brighteners. This also underlines Textilcolor AG’s commitment, as a solution provider, to environmentally-friendly, efficient and future-oriented textile production.

The Textilcolor team looks forward to seeing a lot of visitors on its stand A202 in hall H6 at the ITMA ASIA + CITME 2025 trade fair in Singapore from 28 to 31 October.