#ITMA Asia + CITME Singapore 2025

Innovation and customer proximity – KARL MAYER’s clear focus makes an impression

ITMA ASIA in Singapore, exceeded all expectations for KARL MAYER

KARL MAYER presented itself as a pioneer in its industry – with a clear focus on its core technological areas of warp knitting, warp preparation and technical textiles, as well as on its customers. Attention centred on two machine premieres, the HKS 2-SE TWO and the HKS 4-M EL ECO, along with an accompanying textile show. In addition, ways to generate more and new business through technical textiles for filtration and construction were presented. The showcased solutions for warp preparation aimed at reducing energy and production costs and maximizing efficiency in weaving.

“Our presentation at ITMA ASIA in Singapore impressively demonstrated the strong appeal of KARL MAYER, what a team bursting with energy can achieve, and how important it is to focus fully on innovation and customer proximity. Although the market is still sluggish, I was pleased to see that KARL MAYER is back,” said Lutz Wolf, the new CEO of KARL MAYER.

Warp knitting: Two successful machine premieres, a practical textile show

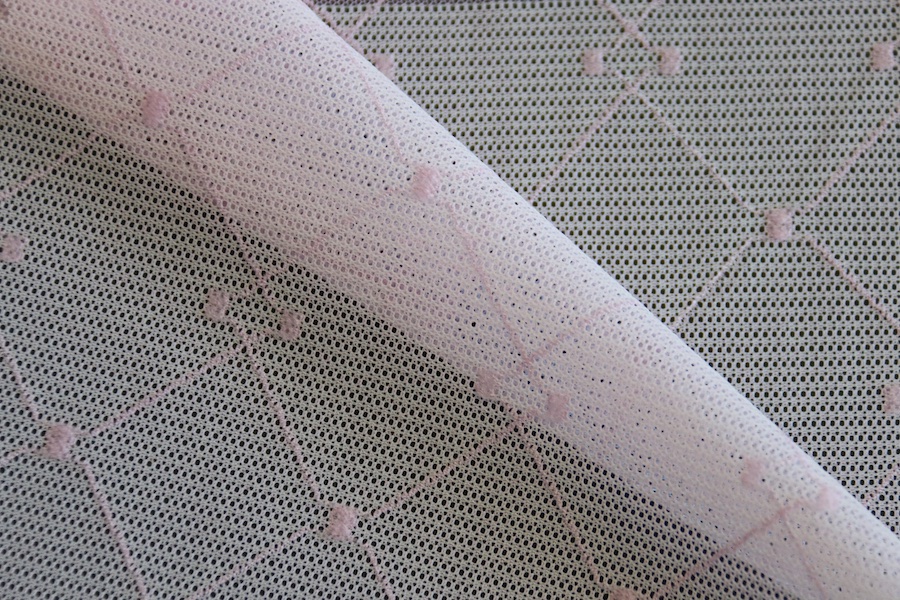

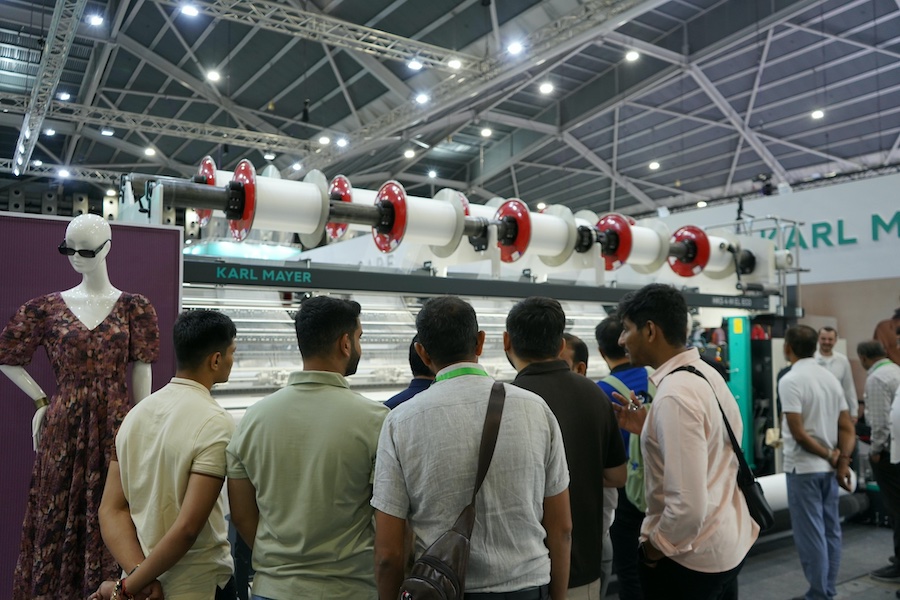

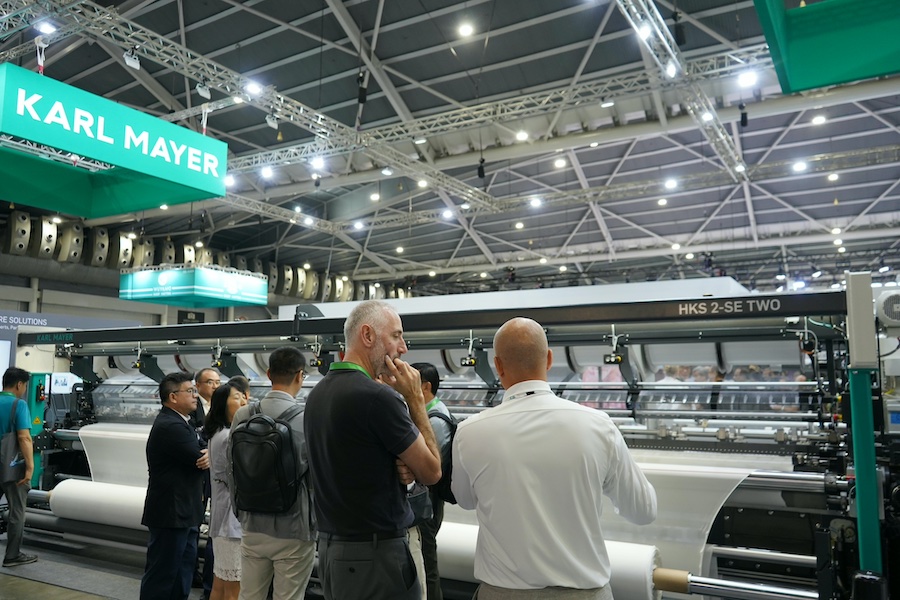

The live demonstration of two new tricot machines – the HKS 2-SE TWO and the HKS 4-M EL ECO – in conjunction with a textile show that showcased the versatility of warp-knitted fabrics and their market potential, made the KARL MAYER stand a real hub for the industry.

“The interest in our four-bar model from the new ECO range and the brand new two-bar TWO model exceeded our expectations. Combined with selected application examples, the machine show was actually the main attraction at our exhibition in Singapore,” says Axel Wintermeyer, President of KARL MAYER’s Warp Knitting Business Unit.

With the HKS 2-SE TWO, KARL MAYER presented a particularly productive and energy-efficient new development offering high fabric quality, low space requirements and low operating costs. The model has set new standards in the field of two-bar tricot machines for the elastic sector and met with great interest, particularly with regard to possible extensions of the TWO concept to other models and variations of knitting motion, reports Michael Ahrendt, Product Owner Global Tricot at KARL MAYER.

The HKS 4-M EL ECO is aimed at warp knitting mills in the fashion sector. It offers high flexibility and versatility for rapid responses to market changes and an attractive price-performance ratio with the proven quality and durability of all HKS models as well as comprehensive support from KARL MAYER.

In addition, a textile exhibition presented matching fabrics and examples of trendy clothing. Both the practical combination of technology and design and the opportunity to exchange ideas with KARL MAYER’s textile experts met with a highly positive response from visitors – customers, brands, designers and product developers.

“We were delighted with the high level of interest, intense technical discussions and valuable feedback – including on possible new textile development projects with key strategic customers in Southeast Asia and from potential new cooperation partners,” said Sascha Müller, Product Owner Global Textile Innovation at KARL MAYER.

In conclusion: with its clear focus on textiles and new textile innovations, KARL MAYER is definitely on the right track!

Technical textiles: multifaceted conversations, new contacts

Visitors from the technical textiles business came with a wide variety of concerns: traditional knitters looking to reorient themselves, fibre producers seeking to expand their value chain to include textile manufacturing, and established industry players interested in discussing plans for weft insertion and composite machines. Hagen Lotzmann expects this to result in orders in the medium term.

“We made numerous initial contacts, but also had many follow-up discussions with starting points for new projects, which we are now pursuing,” says the President of KARL MAYER’s Technical Textiles Business Unit in his satisfied summary of the trade fair.

The topics of the presentation – the construction industry and filtration – led to a lively exchange. In particular, the processing of hollow fibres into filter mats, for example for enriching blood with oxygen, is far from trivial and holds significant potential. Another important topic was personal protective equipment.

Warp preparation: upward trend with uncertainties, positive signals from the Middle East and India

The mood in the warp preparation industry improved in the third quarter but remains marked by uncertainty, as was evident at the KARL MAYER stand, too.

“The number of visitors and the quality of discussions were very encouraging, even though there is still a noticeable reluctance to invest. No one knows how sustainable the upward trend is,” summarizes Dieter Gager, Vice President of KARL MAYER’s Warp Preparation Business Unit.

At present, positive momentum is coming primarily from the Middle East: Egypt wants to expand its denim capacities and increase its creation of value. The aim is to process domestic cotton into fashion and home textile articles in Egypt itself instead of exporting it. KARL MAYER is supporting this development with complete lines for staple fibre processing. Two solutions were successfully presented at the trade fair: CASCADE for reducing energy consumption and CO₂ emissions during sizing on the PROSIZE, and the WARPDIRECT beam warping machine, which offers impressive low-maintenance design solutions.

In India, by contrast, the filament business is developing promisingly, as confirmed by discussions with large industrial conglomerates. KARL MAYER is pursuing a clear strategy here: “We are focusing on quality commodities, export markets and apparel segments, offering India as a reliable alternative to China,” explains Enzo Paoli, President of KARL MAYER’s Warp Preparation Business Unit.