#Knitting & Hosiery

Capsule collection to be launched during Premiere Vision, Paris, 3rd-5th February at the Lenzing stand 6P30

KARL MAYER and Lenzing partner to advance warp knitting with scalable cellulose fiber solutions

Partnership reveals latest innovation project to identify new, efficient ways to process TENCEL™ Lyocell and Modal fibers with Micro Technology, on warp knitting machines

The collaboration focusing on identifying new, efficient ways to process Lenzing’s TENCEL™ Lyocell and Modal fibers with Micro Technology, made from the natural material wood, sourced from certified or controlled sources [1] and manufactured using a responsible production process with a low environmental impact [2], on warp knitting machines, whilst demonstrating their suitability for high-quality textile applications.

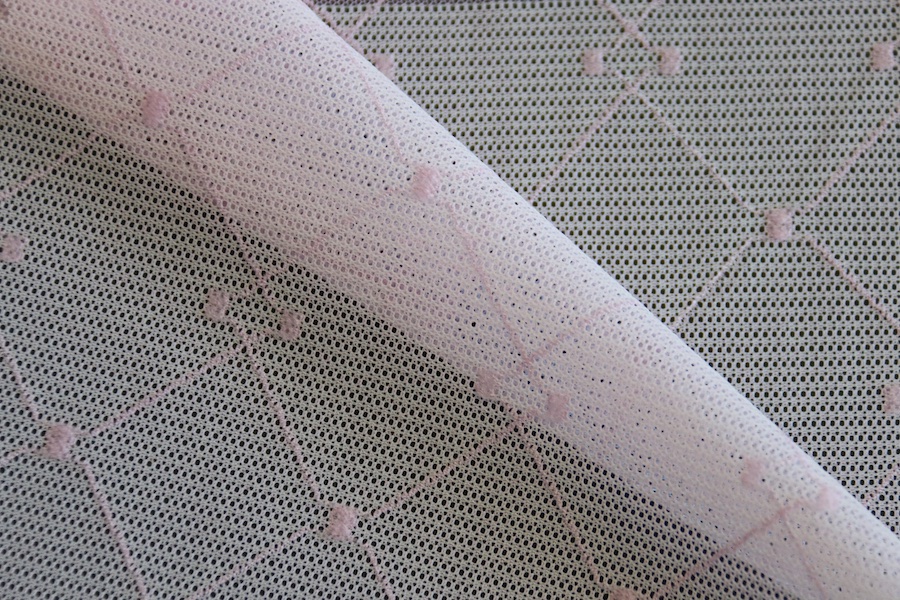

TENCEL™Lyocell and Modal fibers produced with Micro Technology are characterized by their fine titers which enable the production of finer yarns, resulting in smooth and consistent fabrics that deliver softness and lightness for enhanced comfort, whilst yielding superior drape and movement.

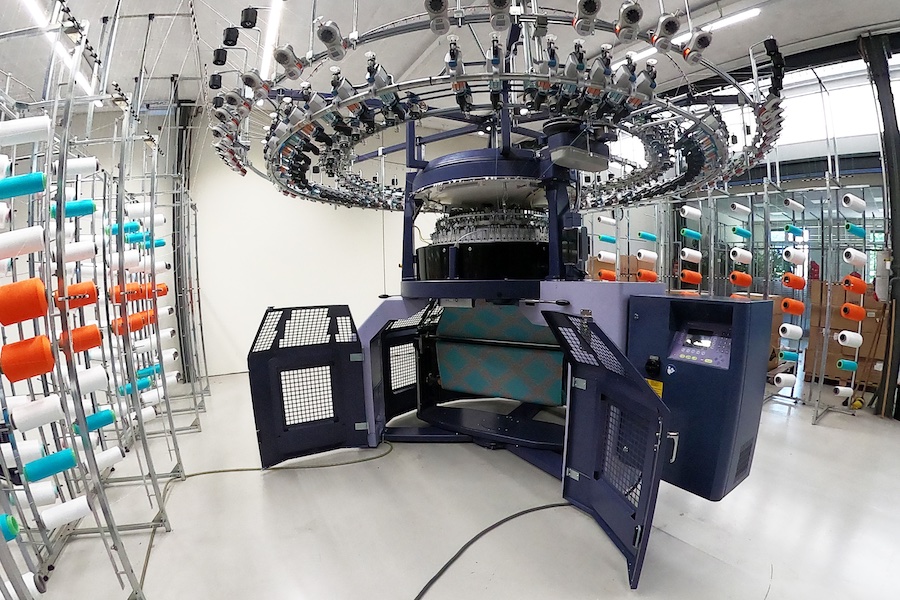

Cellulose fibers offer consistent fiber length uniformity, forming the basis for high mechanical performance. Despite this advantage, the production of warp-knitted fabrics from cellulose fibers presents significant technical challenges. To address this complexity, the two partners joined forces to develop a new innovation project; Lenzing contributing extensive expertise in fiber production and yarn development, including the downstream spinning process, whilst KARL MAYER complemented with many years of experience in warp beam production from staple fibers and their processing on high-performance warp knitting machines. The manufacturer's machines are renowned on the market for their maximum efficiency, reliability and quality.

Yarn properties: Minimal hairiness, homogeneous cross-section

The first step within the project development was to select fibers and spinning technologies that would result in yarns with reduced hairiness. Low hairiness prevents contamination by lint or flying fibers during the beaming and warp knitting process.

In addition, a uniform yarn cross-section is important. A high level of homogeneity of the yarns ensures the tensile strength required to process several thousand threads at maximum speed on KARL MAYER warp knitting machines. Four different yarns were used, each made from two fiber raw materials and two spinning processes.

“We opted for Ring Compact and SIRO Compact spinning technology because it guarantees yarns with low hairiness and better performance and quality of the fabrics made from them,“ says Bernd Schleuchardt, Senior Manager Apparel in the Business Development Division at Lenzing. “By combining fiber innovation with downstream processing expertise, we aim to support scalable, industrial solutions that open up new commercial opportunities for cellulose fibers in warp knitting.”

Specifically, the choice fell on:

1. TENCEL™ Modal with Micro technology Ne 60/1 ( Nm 100/1) Ring Compact – from Gebr. Otto GmbH + Co. KG, 89165 Dietenheim (Germany)

2. TENCEL™ Lyocell with Micro technology Ne 60/1 ( Nm 100/1) Ring Compact – from Gebr. Otto GmbH + Co. KG, 89165 Dietenheim (Germany)

3. TENCEL™ Modal with Micro technology Ne 60/1 ( Nm 100/1) SIRO Compact – from Inovafil - Fiação, S.A., 4770-583 Vila Nova de Famalicão (Portugal)

4. TENCEL™ Lyocell with Micro Technology Ne 60/1 ( Nm 100/1) SIRO Compact – from Inovafil - Fiação, S.A., 4770-583 Vila Nova de Famalicão (Portugal)

Processing: High efficiency, good quality

The yarn material was warped to a high standard, particularly in terms of lint and used on a high-performance warp knitting machine in a gauge of E 28 with two guide bars. This resulted in three different articles for the clothing sector from each yarn: an open worked three-stitch tulle net, a close-knit fabric made counter-lapped open tricot lap and a fabric made from a counter-lapped atlas lap, also with a dense surface.

The processing tests revealed a clear winner: SIRO Compact impressed with significantly reduced hairiness, resulting in less fiber abrasion and less contamination of the machine.

“The project with Lenzing has shown that efficient processing of cellulose fibers on knitting machines is possible by using the right fibers and the right spinning process. We are currently working on optimisations to achieve even higher output,” says Markus Otte, Senior Expert, Textile Development at KARL MAYER.

Debut showcase: Market ready solutions

The results of the innovation project will be presented to the textile world during Premiere Vision, Paris, 3rd-5th February, introducing a capsule collection as a mix of applications across lingerie, innerwear and lifestyle pieces for everyday wear.

The Lenzing team will be at the Lenzing stand 6P30 to welcome guests, engage in discussions on all the latest innovations across the Lenzing portfolio, whilst exploring the new applications across the capsule.