#Knitting & Hosiery

KARL MAYER opens a new TEXTILE INNOVATION CENTRE – a new era of textile innovation begins

Inauguration of the TEXTILE INNOVATION CENTRE with an opening week from 21 to 24 April 2026 in Obertshausen

"With our TEXTILE INNOVATION CENTRE, we are strongly focusing on textiles as the heart of our industry and the growth engine for our customers. The TIC marks a key milestone in KARL MAYER's strategic orientation. We are investing in innovation, quality and partnership-based development so that our customers not only remain competitive, but also have access to innovative textiles that open up new business areas for them," says Lutz Wolf, CEO of KARL MAYER.

The TIC is more than just a building; it is a place for collaboration, creativity and market-relevant solutions – a home for textile innovations. At KARL MAYER’s headquarters in Obertshausen, a “place to be” for the international textile industry is being created: a place that inspires, connects and supports customers in translating their textile innovation into market success. This is where the entire textile world will come together to exchange knowledge, develop ideas, create innovative fabrics on the right machines and make important contacts. This is where the future is being created – with passion, expertise and market focus.

In parallel to Techtextil in Frankfurt, international textile machine manufacturer KARL MAYER invites you to a grand opening week in Obertshausen. From 21 to 24 April, you can experience a thrilling programme of new groundbreaking textile applications, guided innovation tours, expert lectures and networking in a creative atmosphere.

Centre of textile excellence with almost 5,000 m2

“The size and equipment of our new TEXTILE INNOVATION CENTRE are unrivalled in the world,” says Karl Josef Mayer, representative of the Mayer family and patron of the TIC. “Here, we are aiming at the Medici effect basically a renaissance of the textile industry – it’s about preserving and building up textile know-how and textile technology, as well as developing innovative textile solutions.”

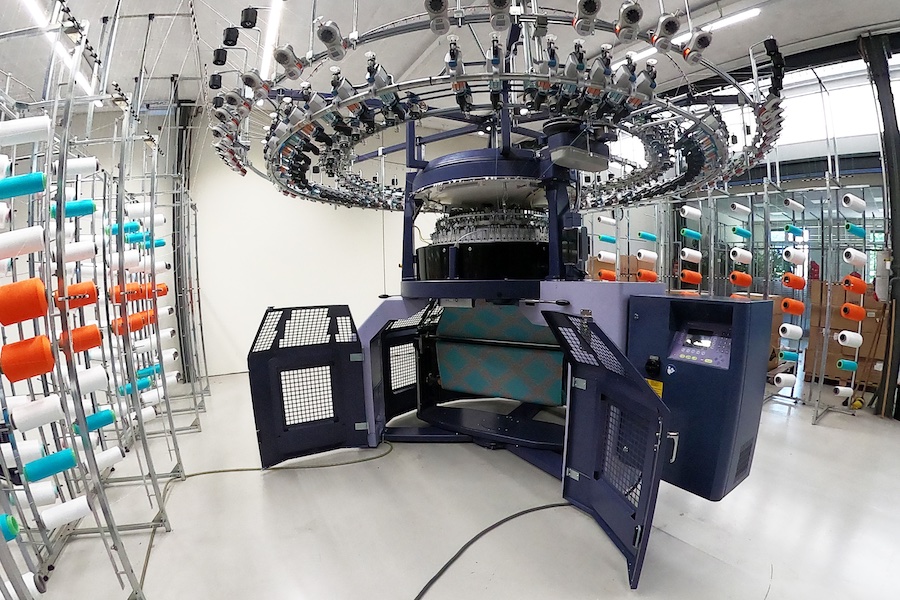

The TIC meets these high expectations with the following offerings:

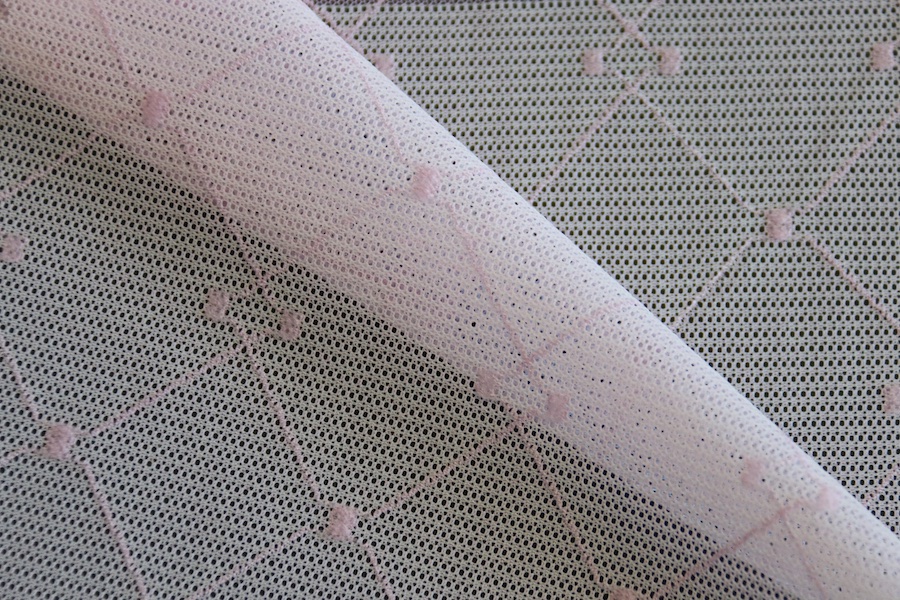

Inspiration at a glance: Insights into proven and promising current textile developments and future trends; a spacious showroom and an open, unique sample archive as an “inspiration hub” invite visitors to think about materials, structures and applications in a new way.

Direct access to top experts: At the TIC, customers will work closely with KARL MAYER’s textile experts. Here they will find the knowledge they need for their innovation process – from material and process know-how to machine and application expertise.

From idea to marketable solution: The TIC will accompany not just customers, but fibre manufacturers and especially brands throughout the entire development process, from the initial idea to the implementation of a near-market prototype on the latest machines. And this goes for all their goals, whether new textile developments, new product launches or sustainable solutions.

Platform for exchange and networking: As an open meeting place, the TIC will bring together the right players from across the entire textile value chain. “Connected Textile Innovation” – from fibre to consumer.

Training courses for professionals: The KARL MAYER Academy, which is well established in the market, will be part of the TIC in future and will offer specialist courses for customer technicians, brand employees and its own service technicians as well as students of textile-related subjects.

KARL MAYER looks forward to welcoming customers, partners and the international trade press to the TEXTILE INNOVATION CENTRE in Obertshausen during the opening week.

Save the date: 21 to 24 April 2026, Obertshausen – in parallel to Techtextil Frankfurt.

Pre-registration at:

https://forms.office.com/pages/responsepage.aspx?id=wN-xQvoWVUme0yq53uw9Hp6EVE41oPtGtA5BADYEQ1BUME1NQlczNDNSUVBOR0wxRTdBUkc1RDA0UC4u&route=shorturl