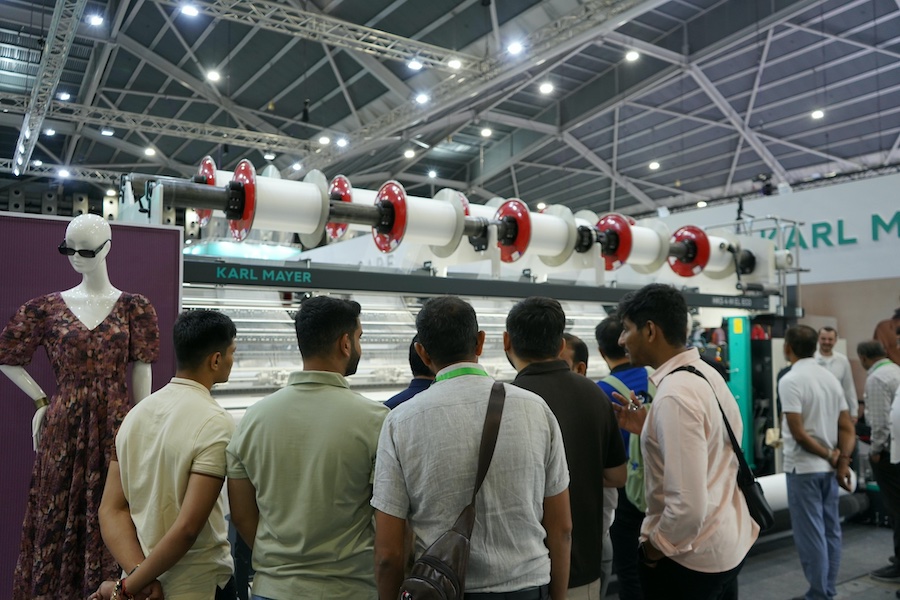

#ITMA Asia + CITME Singapore 2025

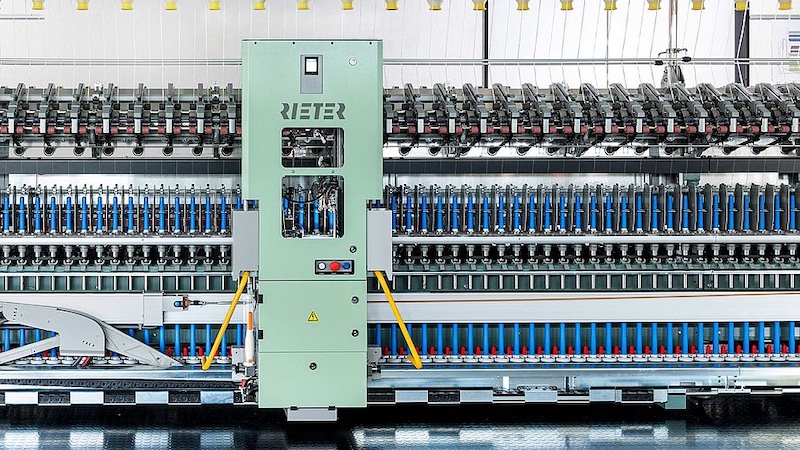

Rieter will highlight the fully automated spinning mill at ITMA Asia 2025

Automation and digitization – the smart gateway to the future

Rieter will be presenting solutions that enable the step-by-step implementation of the fully automatic spinning mill for the production of ring and compact yarn. Highlights include efficient bale transport, automated can transport and fully automatic packaging solutions, such as steaming, palletizing and labeling. In the field of digitization, Rieter offers various ESSENTIAL modules to meet different requirements. This gives spinning mill employees – from management to machine operators – a solid basis for making decisions on how to optimize yarn production.

Leading the way in combing preparation – the OMEGAlap E 40

The new combing preparation machine OMEGAlap E 40 produces 800 kg/h, 33% more than its predecessor – thanks to the rapid lap changing. At the same time, it boasts 30% lower energy consumption and 63% lower compressed air consumption. Maintenance and cleaning are especially easy, representing a clear advantage for operating personnel.

The precision winding machine NEO-BD – faster and better

The new precision winding machine NEO-BD produces packages twice as fast as the previous model – and to a higher quality. Absolute precision is guaranteed: from the optimally adjustable package density and the yarn length that can be defined and reproduced with maximum accuracy to the exact weight of each individual package.

Efficient air-jet spinning of carded cotton

The air-jet spinning machine J 70 is designed for cost-effective carded fiber spinning – a unique feature made possible thanks to a newly developed twist element: it takes the production speed to a new level and ensures maximum return when it comes to raw material utilization. Spinning mills also benefit from the use of this innovation in other raw material applications.

The spindle that saves energy – eNASA

The new Novibra spindle eNASA reduces a spinning machine’s power consumption by 2% to 4% compared to conventional spindles. The high-precision technology is particularly effective at high speeds. The new spindle is compatible with all Novibra clamping crowns.

Technological expertise in recycled yarn

Rieter works closely with partners and fiber manufacturers on the topic of recycled yarn. As part of this, different projects and end products will be presented. One new way to significantly increase the recycled content of ring yarn involves the use of sustainable, synthetic cellulosic fibers – described in detail in a new technology publication.

New Rieter Webshop – the smarter, faster way to source spare parts

The state-of-the-art platform is a smart solution enabling customers to procure spare parts for spinning and winding machines, upgrades and retrofit solutions. The one-stop shop experience simplifies and optimizes ordering for every spinning mill.

Rieter will present its latest products and solutions at ITMA ASIA + CITME 2025 in Singapore from October 28 to 31, 2025, in Hall 3, Stand A201b. With sophisticated technologies, products and services that guarantee the highest quality and enable economical, flexible production, the company is able to position itself as a reliable partner for spinning mills.