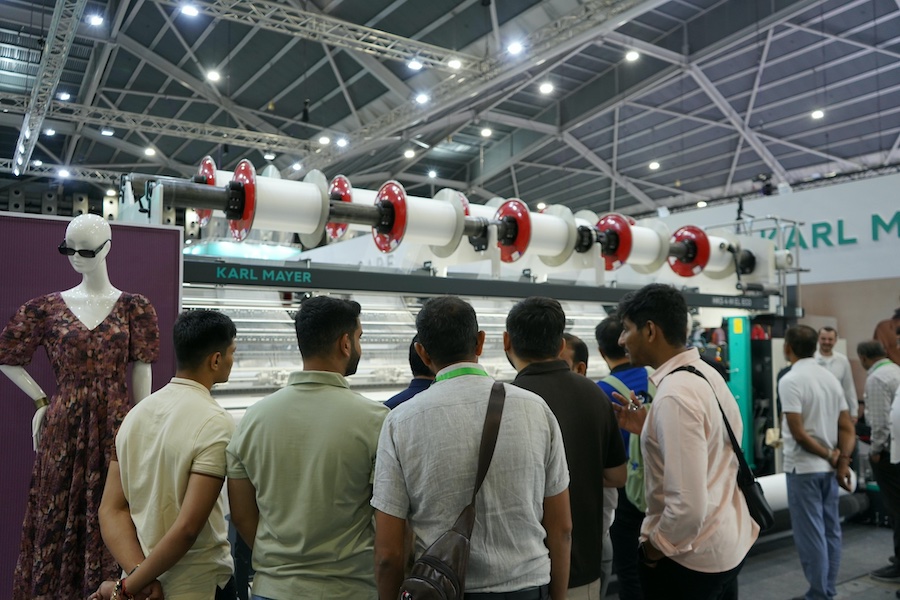

#ITMA Asia + CITME Singapore 2025

Saurer’s leading technology for the yarns of tomorrow at ITMA Asia 2025

Highlights on the booth include the Autocard SC8 with Autocoil 3 featuring the PDS Pre-Draft System and rectangular cans, the new Can AGV Hunter S1 for can transport, the Zinser 51 ring-spinning machine with the new compact system Zpact FX, the Autocoro 11 rotor spinning station with the Duo Sliver Feeding concept and the CompactTwister.

Fashion and interior design start with yarn: structure, characteristics, such as stretch or hairiness, and occasionally even colour starts already during the spinning or twist-ing process. Saurer’s state-of-the-art machinery, automation and services are designed to help textile manufacturers optimise production processes, remain flexible, and save resources. Visit booth C301 in Hall 3 to see details on the innovations, engage with the experts, and discover how the company Saurer is shaping the future of textiles.

“Leading technology for the yarns of tomorrow - this is what drives us at Saurer to develop innovative solutions for spinning and twisting mills worldwide. We are excited to demonstrate in Singapore how Saurer’s forward-thinking solutions empower textile manufacturers to stay competitive in a rapidly evolving global market,” says Hailin Xu, CEO of Saurer.

Spinning preparation - the first step towards excellence in yarn

At ITMA Asia in Singapore, Saurer will present the new high-performance card Autocard SC8, designed to deliver superior yarn quality, higher productivity, and optimised energy efficiency for modern spinning mills. The Autocard SC8 features an impressive 4.8 m² carding area, achieved with a 1.38 m carding width and 1.46 m cylinder diameter. Its smart design and optimised licker-in and doffer positioning extend the carding section length and boost efficiency.

Saurer will present the new Autocoil 3, featuring the PDS pre-draft system and rectangular cans. These pre-drafted slivers can be used directly on rotor spinning machines, enabling spinning mills to achieve an ultra-short process. Compared to round cans, the compact rectangular cans have a higher storage capacity for slivers, thereby reducing the frequency of can changes.

This combination ensures excellent yarn quality, enhances production efficiency and energy utilisation, and offers new ways in pre-spinning.

Saurer’s innovative Can AGV Hunter S1 automates the transportation of sliver cans, boosts efficiency, reduces manual handling, and saves valuable workforce resources in the spinning mill. The Can AGV offers flexible solutions to meet a wide range of customer requirements. Designed for the efficient handling of sliver cans across departments, including carding, drawing, roving and rotor spinning, it is highly versatile and can be used in a wide range of applications.

The Can AGV Hunter S1 can also be fully integrated with the Saurer Senses Mill digital management system, further enhancing the synergy between automation and digitalisation in spinning mills.

Spinning with countless possibilities

The Zinser 51 ring spinning machine with 2056 spindles combines precision engineering with smart automation, enabling maximum productivity, consistent yarn quality, while achieving remarkable energy savings. Thanks to its new compact device Zpact FX, the Zinser 51 compact spinning machine achieves the highest speeds while maintaining perfect fibre control.

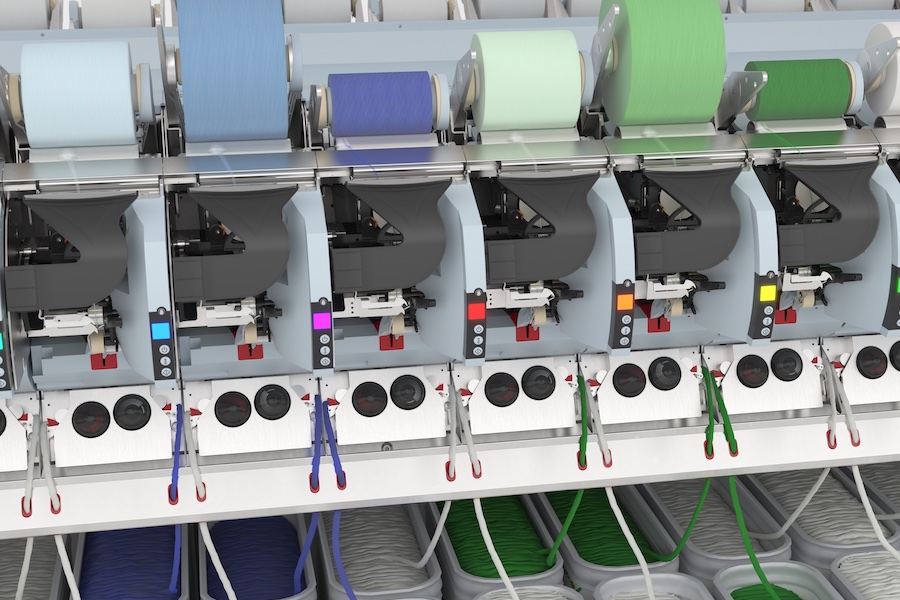

Enabling unmatched flexibility, Autocoro 11 rotor spinning station will be equipped with the new Duo Sliver Feeding concept, taking rotor spinning technology to the next level. At ITMA Asia, Saurer will demonstrate this concept with a spinning box with two opening rollers that can transform mélange and blended yarn production. Blending two different slivers directly on the Autocoro, adjustable in 1% increments, opens a whole new world of spinning possibilities, resulting in maximum reproducibility and the finest nuances. Reducing pre-spinning costs and enabling the economical production of coloured mélange yarns in smaller batches are additional benefits.

Saurer will also be showing the Autoairo air spinning station with different fibre compositions. BD 8 is the longest semi-automated rotor spinning machine with a maximum of 1200 positions, incorporating the energy-saving Twinsuction system and an automatic doffer for package changes. The Texparts components for ring and rotor spinning ensure the highest yarn quality.

Twisting makes a difference

While staple fibre twisting used to be reserved for the finest materials and yarns in the past, the new demand to increase the strength of recycled yarns has opened up a whole new market segment. At the booth, Saurer will exclusively showcase the CompactTwister, which sets the benchmark for yarn quality, flexibility, energy efficiency, robustness, space-saving, and ease of maintenance. Its comprehensive twisting portfolio comprises intelligent and economical twisting and cabling machines for tire cord, carpet, staple fibre, glass filament, and industrial yarns.

Catering to the market's need for recycled and regenerated yarns, Saurer's machinery portfolio for staple fibre spinning and twisting is developed not only for the highest productivity, but also to offer excellent solutions from bale to yarn for processing even the shortest recycled fibres.

Saurer looks forward to welcome visitors in Singapore at booth C301 in Hall 3!