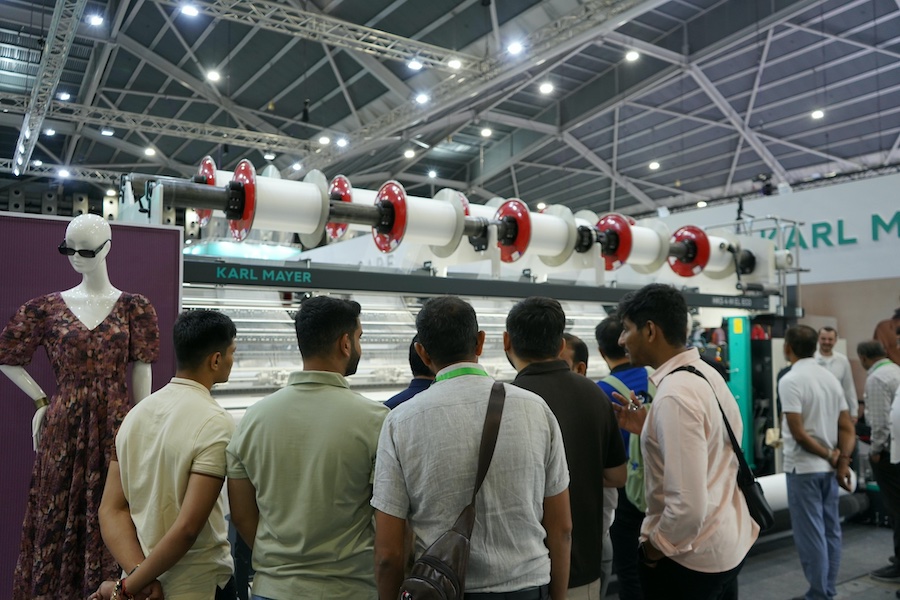

#ITMA Asia + CITME Singapore 2025

Marzoli unveals its new textile ecosystem at ITMA ASIA + CITME 2025 at Singapore

Marzoli, a global benchmark in spinning technology and part of the Camozzi Group, will be at ITMA ASIA + CITME 2025, held in Singapore from October 28 to 31. Visitors will find Marzoli in Hall 3, Booth D301, under the new claim “Design to impact – Turning advanced solutions into strategic advantage.” With this statement, Marzoli presents itself as a leading company capable of shaping demand and driving innovation across the entire textile supply chain, with a focus on : luxury & fashion, denim and technical textile.

Thanks to its deep technological and process know-how in machinery, combined with significant R&D developments, Marzoli will launch high value-added services through its Technology Accelerator Center (TAC). This evolution allows the company to enrich its traditional machinery offering with innovative solutions that address the major challenges faced by textile players.

Within t he Technology Accelerator Center (TAC) , visitors will discover a dedicated range of services :

- Recycled yarn. Thanks to Marzoli’s patented Refiber machine , the company creates advanced recycled fibers offering superior strength and quality compared to standard recycled ones. A true second life for textile s waste —on display at the booth .

- Functionali zed yarns. With a new patented process, Marzoli enables next-generation yarns enhanced with nano fibers , combining the natural feel of original fibers with exceptional new properties.

- Digital Suite an d TexTrack Platform. The Marzoli Digital Suite provides integrated digital tools for remote control and predictive maintenance , plant and production management , and performance optimization , while TexTrack ensures complete supply chain transparency through advanced traceability functions.

- Reengineering Solutions. Marzoli will also showcase its modular reengineering approach designed to evolve and upgrade spinning machines, improving efficiency and lifecycle performance. Through these innovations, Marzoli confirms its mission: to design solutions that create measurable impact , empowering textile manufacturers to turn advanced technology into a true strategic advantage.

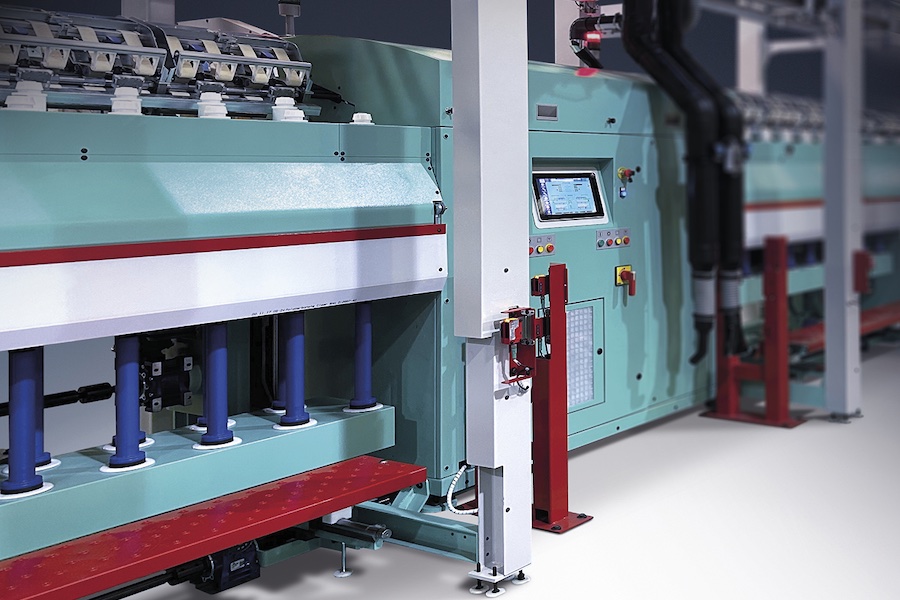

“Alongside our traditional machinery offering, Marzoli is moving decisively toward integrated solutions designed to address the textile industry’s key challenges.This strategic shift positions us as a long-term partner, not just a supplier.” – comments Cristian Locatelli, General Manager of Marzoli. Among other important highlights on display at Marzoli’s booth, also the roving frame FTM320

This machine features a central headstock and independent double -side modules operating simultaneously, increasing spinning efficiency by up to 5%.Alongside the machine, Marzoli introduces MARTE, the new bobbin transport system equipped with a roving waste recovery function and an innovative real -time stock monitoring capability. Together, the FTM320 and MARTE represent a new standard in automation and efficiency for spinning preparation. And, last but not least, Marzoli in cooperation with 3 customers, DNM Denim, Botto Giuseppe and Tempo test will allow visitors to see and touch denim, cashmere, wool and technical textile produced by its technologies.

Visit Marzoli at ITMA ASIA + CITME 2025 Hall 3 – Booth D301