#Nonwovens

Turning diaper waste into new value: BASF, Essity and TU Wien pioneer circular solutions

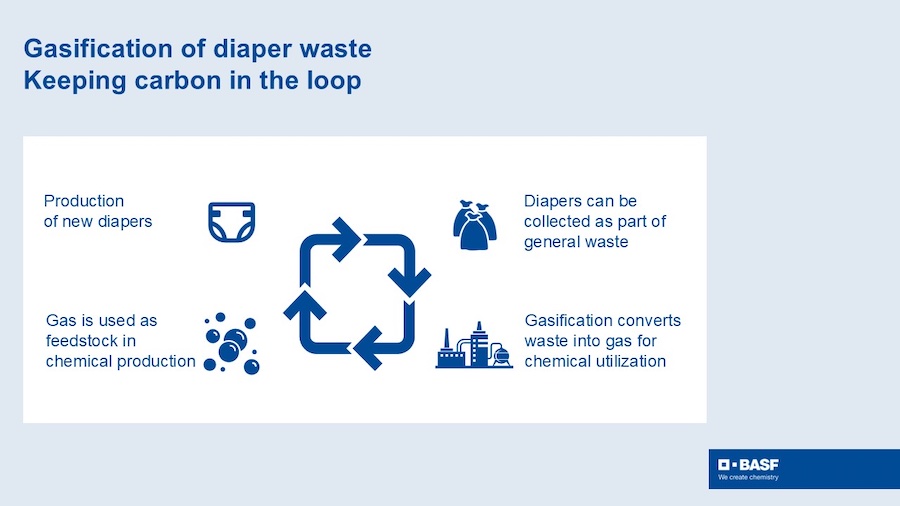

The groundbreaking gasification pilot project proves that used diapers and other absorbent hygiene products can be transformed into valuable raw materials for new chemical products – no complex pre-treatment required. The resulting gas mixture contains carbon monoxide and hydrogen, which can be used as feedstock in chemical production, keeping carbon in the loop.

BASF and TU Wien’s innovative gasification technology enabled this result. Gasification is a process that converts solids like waste into gas at high temperatures above 600 °C. Thanks to this process, diaper waste is sanitized and converted into high-quality feedstock, matching the standards of virgin resources.

This breakthrough not only tackles a major waste stream but also unlocks possibilities for circularity in the chemical and hygiene sectors. This scalable solution has the potential to reshape municipal waste management, helps our customers achieve ambitious sustainability goals and offers a solution to diaper waste.

BASF’s unique production network enables the use of recycled feedstocks, offering customers products that are both sustainable and high-performing.

“Our customers can rely on BASF as their trusted partner for innovative recycling solutions. We demonstrated the potential of recycling post-consumer absorbent hygiene products. BASF is committed to turning challenges into opportunities and leading the way towards a more sustainable future—together with our customers,” says Oliver Cullmann, Vice President Global Marketing & Strategy C3 Value Chain.