#Recycled_Fibers

Odlo and DePoly “Close the loop” on Polyester with InnoBooster project

Building on Odlo’s long tradition of sustainable innovation, the project set out to explore whether waste from Odlo’s own production could be reborn as the brand’s first circular base layer.

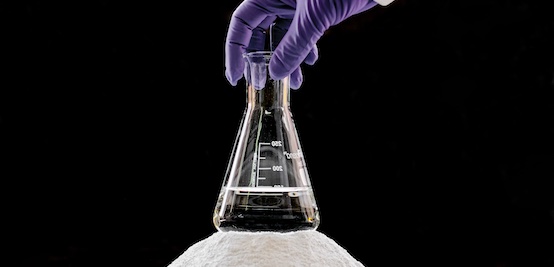

The journey began in Romania, where cut-offs from Odlo’s popular Active Warm base layers were collected and diverted from the waste stream. In Switzerland, DePoly applied their patented recycling process to break the fabric down into the monomers of polyester, restoring the material to its original purity. These monomers were then repolymerised into virgin-quality PET pellets in Italy, before being spun and knitted into new performance fabric in Spain.

“Our mission at DePoly is to make circularity for synthetic materials – textiles and plastics alike - a reality,” said Tijana Ivanovic, Senior Business Development Manager at DePoly. “Working with Odlo on this project demonstrates the quality and impact chemical recycling can deliver.”

The initiative was supported by an InnoBooster grant from Innosuisse, the Swiss Federal Innovation Agency. The programme backs radical ideas for highly circular products and systems across Swiss industries, with this project chosen from among several applicants.

The result is more than a technical success. It is proof that textile waste can return as fabric equal in quality and performance to virgin polyester.

Why it matters

Polyester is the backbone of today’s textile industry, making up more than half of all fabrics worldwide. Yet less than one percent of that material is recycled back into textiles, leaving the vast majority to be downcycled, landfilled or incinerated.

For brands with strong sustainability ambitions, this gap has long been a stumbling block. The Odlo–DePoly project demonstrates that chemical recycling can offer a way forward. It creates a closed loop for synthetic fibres, reduces reliance on virgin fossil-based resources and keeps materials in circulation.

This work furthers Odlo’s “Close the loop” circularity ambitions, which encompasses product longevity and traceability. The approach is rooted in Odlo ReWEAR, an initiative that gives garments a second life through repair, resale and take-back programmes. By investing in circular technologies such as chemical recycling, Odlo is extending this vision to cover not only how products are used, but also how they are remade.

“Closing the loop requires more than one solution,” said Johanna Heimlicher, Sustainability Director at Odlo. “By combining initiatives like ReWEAR with cutting-edge recycling technologies such as that of DePoly, we are laying the groundwork for a truly circular approach to performance apparel.”

Looking ahead

The successful completion of this project is just the beginning. For Odlo, it marks an important step in bringing its “Close the loop” vision to life. The next phase of work will focus on developing product prototypes, defining design criteria and exploring wider collaborations that can help establish a circular ecosystem for polyester in Switzerland and beyond. By closing the loop on polyester, Odlo and DePoly are not only addressing textile waste but also creating a model for how circularity can scale across the industry.