#Spinning

Mei Sheng in Vietnam: Longstanding partnership for outstanding quality

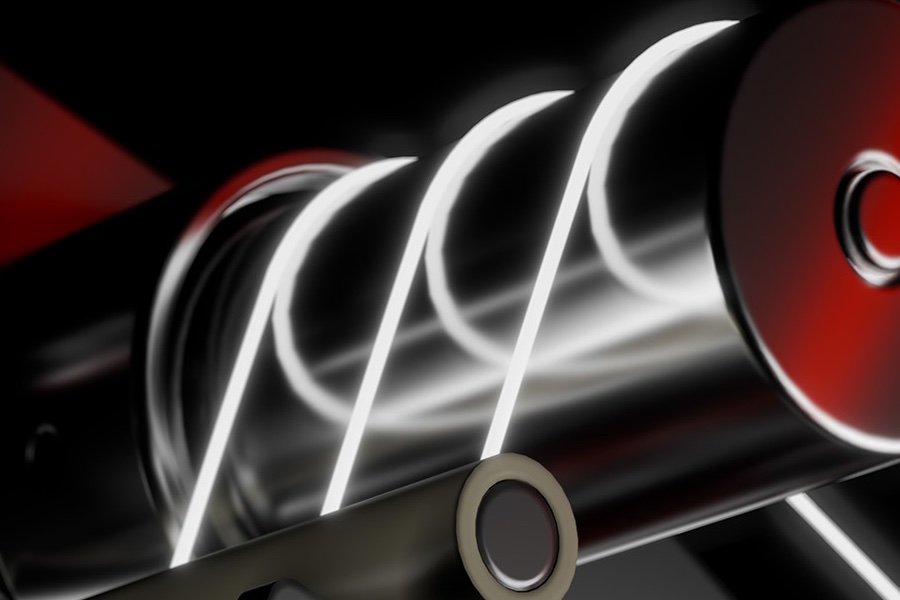

During the last three decades, Mei Sheng has risen to become a leading player in the Vietnamese textile market – and a valued supplier of top-quality yarns for customers worldwide. The company is located in Ba Ria Vung Tau province, close to Ho Chin Minh City. It produces compact, ring, Murata Vortex, rotor, siro, slub and melange yarns and knitted fabrics.

How would you describe your company and its decision to choose card clothing from Trützschler?

We’re a growing company that makes a uniquely wide range of yarns. Our products flow into markets around the globe. That means we need to meet special demands, certification standards and performance expectations for a huge variety of customers and regional markets. We’ve achieved success because of our commitment to outstanding quality, which is at the heart of everything we do.

That’s why we chose to work with Trützschler in the early days of our company and it’s why we still rely on them to supply 100 percent of our card clothing requirements today. They offer superior durability and precision to ensure consistent and excellent yarn quality. In total, we operate 172 Trützschler carding machines.

Why do you value your company’s partnership with Trützschler so highly?

Mei Sheng has bold ambitions and Trützschler enables us to achieve progress toward those business goals. Their experts are always nearby and available to provide rapid, effective support. And they share their deep technical knowledge with our teams to solve problems, maximize efficiency and optimize the performance of our processes. We truly value that highly professional collaboration.

Trützschler’s team immediately offers special training whenever we need it, while also providing ongoing guidance for how to adjust our machine settings for specific raw materials or market expectations. Teams from Trützschler often visit our sites to solve problems, discuss our evolving needs and provide trusted consultancy. On top of this, Trützschler has a local stock of card clothing, so we never face emergency stoppages or machine downtime.

What do you expect for the future of your business and the textile market?

The global textile industry is highly complex and always difficult to predict. Right now, there is economic uncertainty in many markets and regions. In this context, Mei Sheng needs to stay flexible and maintain its sharp focus on outstanding quality to achieve our ambitious plans for expansion.

We have created a strong foundation that is built on close partnerships with businesses that share our commitment to quality – like Trützschler. They are setting new benchmarks for excellence in textile manufacturing and have a proven track record of supporting innovative companies like Mei Sheng with high-performance machines and fast, local service that enables success. Our two companies are connected by quality. Now, we want to keep moving forward together.

The interview was conducted by Umesh Kalyanappa.