#Weaving

Stäubli demonstrates how innovation translates into real benefits for weaving mills at SITEX 2026

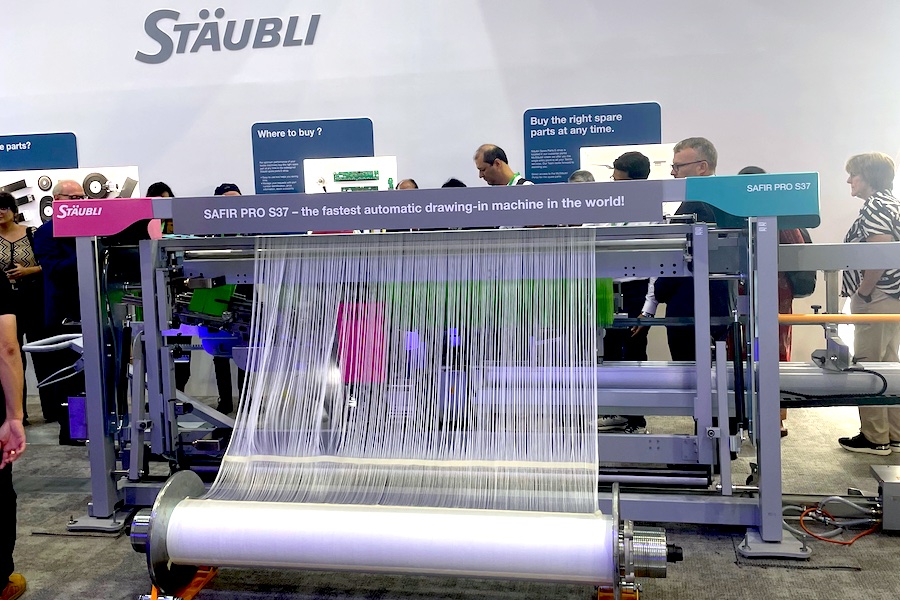

Stäubli booth atITMA Asia in Singapore © 2026 TexData International

At Booth 242, visitors will discover how the company’s latest advancements help weaving mills achieve higher speed, precision, and fabric quality.

Among the innovations on display, Stäubli is putting a special spotlight on the S3018 rotary dobby for waterjet weaving machine, engineered to deliver outstanding reactivity and high running speed on water‑jet weaving machines. This model offers stable and optimised lifting performance, supporting mills seeking greater versatility.

For Jacquard weaving, the LX PRO represents the next‑generation Jacquard machine renowned for its exceptional precision. Displayed with a weaving loom for saree applications, the LX PRO Jacquard machine is equipped with TC8 controllers and NOEMI electronics, it delivers high energy savings, precision, and reliability, attributes that have made it a preferred solution among Indian mills.

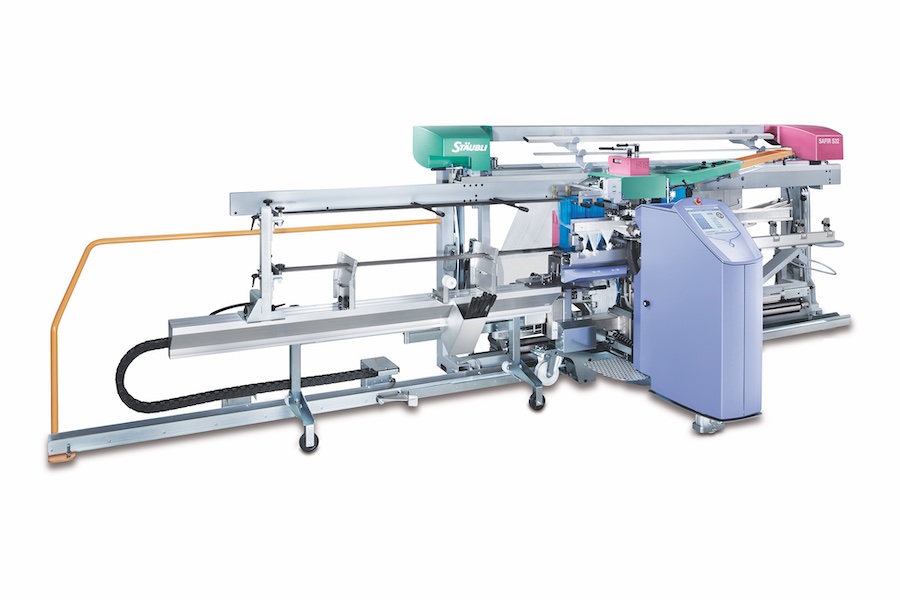

Alongside these key solutions, Stäubli will also showcase its automation systems for warp preparation, designed to reduce downtime and accelerate style changes: solutions like the SAFIR S32 drawing-in system and TOPMATIC and TIEPRO warp tying machines.

Together, these technologies offer textile manufacturers a comprehensive answer to the current challenges of productivity and fabric excellence. They reflect Stäubli’s philosophy: combining mechanical robustness, smart electronics, and power optimization to strengthen the competitiveness of Indian weaving operations.

With more than 130 years of expertise in developing high‑performance equipment, Stäubli continues to support weaving mills worldwide by providing durable, efficient solutions that are perfectly aligned with their production requirements.