#Composites

Breaking new ground in Technical Textiles: Stäubli at JEC World 2026

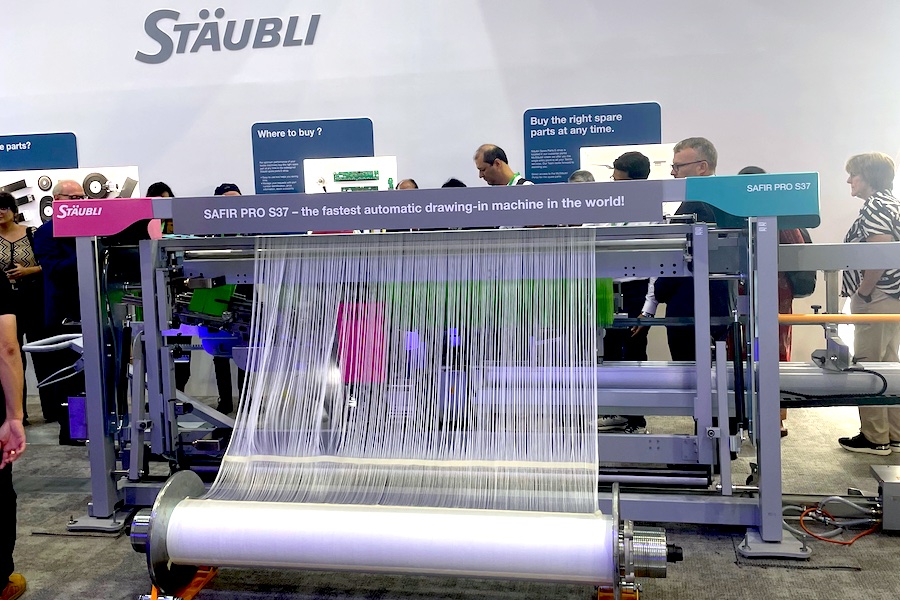

As the leading international trade show for composites and advanced materials, JEC World brings together key innovators, manufacturers, and technology providers from around the globe. With more than 130 years of experience in the weaving industry, Stäubli continues to shape the future of technical textiles by delivering highly reliable, high-speed weaving machinery and fully integrated solutions for advanced applications.

Visitors and partners are invited to discover Stäubli’s trend-setting technologies at Booth M141 in Hall 5.

At this year's edition, Stäubli will place a special focus on its UNIVAL 100 electronic Jacquard machine, which provides unparalleled flexibility for weaving complex and sophisticated technical fabrics. Featuring individually controlled harness cords and exceptional motion precision, the UNIVAL 100 is particularly suited for 3D weaving and the processing of demanding materials such as glass and carbon fibers. Its fully electronic architecture enables unlimited pattern versatility while ensuring gentle control and optimal yarn handling, critical factors in high performance composite applications.

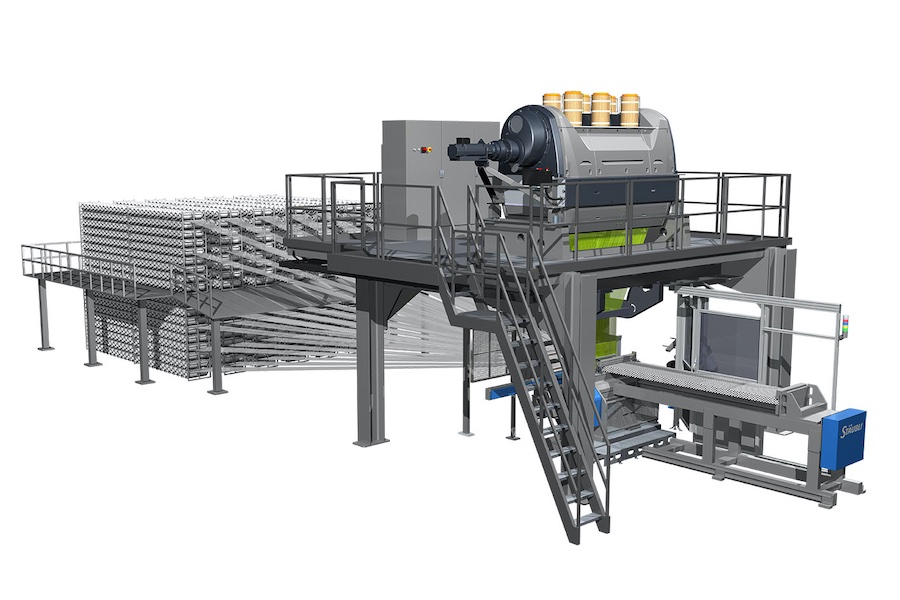

Stäubli will also present its TF series weaving machines, engineered for the production of advanced 3D and multilayer fabrics using materials such as carbon, glass, and aramid fibers. The TF20 and TF30 models combine flexibility, precision, and productivity, making them ideal for manufacturing lightweight composites, aviation-grade materials, and reinforcement textiles for construction. Designed for high performance weaving, the TF20 offers high-speed capability and a double rapier option that can significantly boost output, while the TF30 ensures gentle yarn handling and supports a wide range of sophisticated weave structures.

Stäubli’s commitment to excellence is rooted in continuous R&D, the use of superior-quality components, and long-term customer support before, during, and after machine installation. Stäubli equipment operates reliably in weaving mills worldwide, producing technical fabrics that meet the most stringent performance standards, from lightweight reinforcement structures to specialized industrial textiles.

Visitors to Stäubli’s booth will have the opportunity to explore how the company’s integrated weaving solutions support the development of next generation composite materials and open new possibilities for industrial innovation.