#ITMA Asia + CITME 2024

What’s new in warp knitting?

At the upcoming ITMA ASIA + CITME, the KARL MAYER GROUP's exhibition program will focus more than ever on the challenges facing its customers. In a time, full of upheaval, the motto of the innovation show is “Master the Change”. Companies in the warp knitting industry must also react flexibly to volatile markets, operate profitably and sustainably, manage with fewer skilled workers and, above all, generate more and new business. Despite full warehouses and stagnating demand, it is important to place warp knitted products even better in existing business areas, but also in new markets. KARL MAYER will be demonstrating how this can be achieved at stand C27 in hall 4 of the Shanghai National Exhibition and Convention Center from October 14 to 18, 2024.

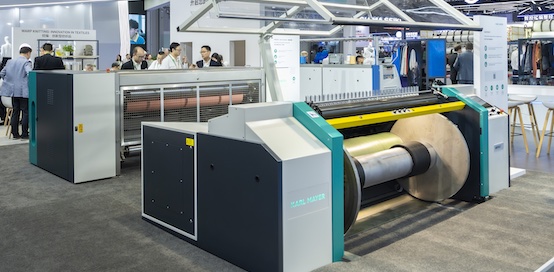

“Our trade fair machine, a two-bar high-performance tricot machine in gauge E 44, offers an impressive production speed in the manufacture of extra-fine fabrics and thus opens up interesting new perspectives, particularly in the outdoor clothing sector. In addition to the machine, we will be focusing on textiles with great market potential at the trade fair. The majority of this will be devoted to outerwear, but innovative articles for end applications in the underwear, sports and automotive sectors will also be on show,” explains Christof Naier, Presiden of the Warp Knitting Business Unit.

There will also be a presentation of new Care Solutions offerings, including the Energy Efficiency Solution (EES) for greater sustainability and the myKM.ON Customer Portal, which gives users access to the digital world of the KARL MAYER GROUP.

The digital solutions will be presented by KM.ON. The Digital Production Management (DPM) for real-time insights into production processes and the ki-based Quality Monitoring System (QMS) are part of the exhibition program for the warp knitting sector.

An in-house show accompanying the trade fair at KARL MAYER (CHINA) in Changzhou will showcase seven selected warp knitting machines for a wide range of applications at work. “Both proven high-tech machines and some completely newly developed mid-range machines will be on display. The aim of our exhibitions is to demonstrate our technological leadership to our customers worldwide and to provide them with solutions in various price categories,” says Christof Naier.

The in-house show begins on October 13 and will feature a special highlight with the opening of a new showroom at KARL MAYER (CHINA).

Innovations with promising market potential

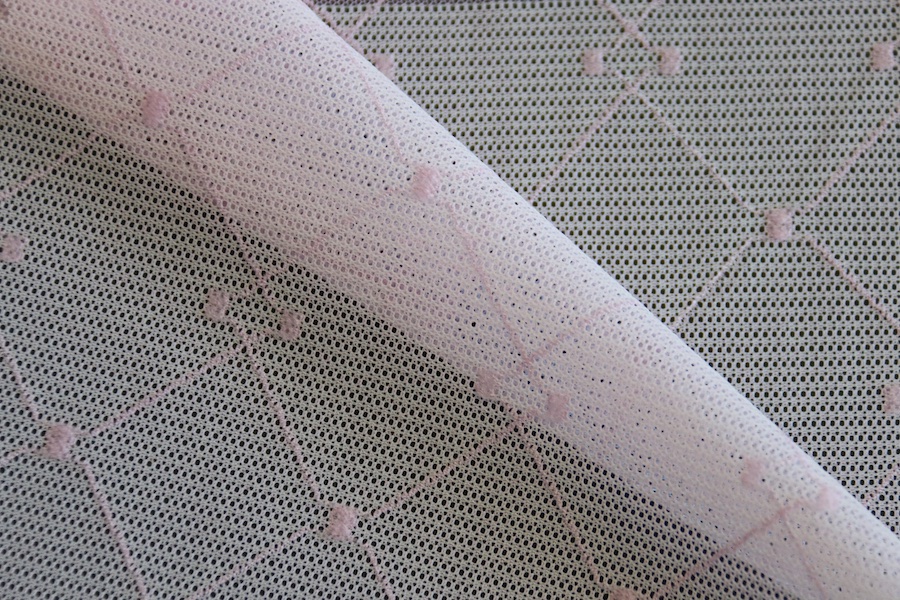

The machine highlight at the trade fair stand in Shanghai is an HKS 2-S in the new gauge E 44. The high-performance tricot machine gets the outdoor fashion sector moving with its unique efficiency. It produces up to 200 kg fabric per day and therefore scores significantly better in terms of price-performance ratio than counterparts from other technology sectors. The performance profile of its textile products is also impressive. An extremely compact structure ensures optimum climate adaptation and a high level of comfort, while 360° stretch ensures maximum freedom of movement and a perfect fit. The soft, silky surface also creates a pleasant second-skin feel. An exceptional combination of comfort, function and a touch of luxury, that opens up far-reaching market opportunities for the new E44 items, particularly in the outdoor wear sector!

Other promising textile innovations include sportswear items for the growing yoga trend, which has been fueled by the national “Healthy China 2030” initiative since 2016. Functional, stylish leggings made from a fabric produced on an HKS 2-S, E 40, will be on show. Clothing fabrics with the look of typical woven fabrics are also an important topic. The warp knitted alternatives are comfortable to wear, easy to care for, do not crease and are produced using sustainable technology. The exhibits include a chic ladies' suit made from a tricot fabric produced on an HKS 3-M ON, E 32, comfortable casual wear outfits made from fabrics from a TM 2-SE, E 36, and a down jacket with a top layer made from an E 40 warp knitted fabric from an HKS 2-SE. The two-bar HKS machine also contributed fabrics for the trend topic of sun protection clothing.

Colorful spacer fabrics with diverse plastic surface effects make garments and accessories with completely new looks possible, as shown by the extravagant articles from RDPJ 6/2 EL machines, both as multicolor variants and with filler bar equipment for 4D Knit products.

When feminine chic is required, the fabrics from KARL MAYER's Raschel machines come into play. An article made of raw silk from an RJ 4/1 EL in E 32 was turned into elegant nightwear and a powernet from the new RE 4-1 in E 32 into a distinctive ladies' dress. The newcomer is selling extremely well in China, also in E 36, which is why a 190? model was added to the previous 170" version of the RE 4-1 in E 36. The highly productive Raschel machine with the larger working width is a highlight of the in-house show in Changzhou.

Of course, the delicate items from the KARL MAYER lace raschel machines must not be missing at ITMA ASIA + CITME!

When it comes to lace, the global player is focusing even more closely on the standard Leavers Lace, combining new jacquard construction techniques with clever drawing techniques. Creations from an MJ 92/1 F with the brilliant design image of Symm-Net and unsurpassed complex patterning effects will be on show. Other eye-catchers are delicate TEXTRONIC® items from an MT 84/1/40 S in E 24 with a unique interplay of transparency and plasticity rich in contrast.

In addition to clothing textiles, shoe fabrics are more popular than ever before. Trendy spacer fabrics from RDJ machines with one and two Jacquard bars will be presented.