#ITMA Asia + CITME Singapore 2025

Trützschler invites to discover the future of fiber processing at ITMA Asia Singapore 2025

Trützschler Spinning

At the heart of the Trützschler booth, visitors will discover the latest automation innovation T-CAN – a smart system designed to revolutionize sliver transport in spinning preparation. While full details will be unveiled at the show, this solution reflects Trützschler’s commitment to simplifying operations and boosting efficiency through intelligent technology. Alongside this innovation, they will also showcase the proven next generation card TC 30i. Depending on the raw material, but especially in the field of man-made fibers, the TC 30i achieves up to 40% higher productivity compared to the current benchmark, while maintaining or even improving yarn quality. A sophisticated waste suction system enables the separate collection of different waste types, allowing more than 50% of card waste to be reused in a high-quality manner. The TC 30i also comes with the proven WASTECONTROL system, an easy-to-use and effective assurance against unnecessary fiber loss.

The IDF 3 integrated draw frame complements the TC 30i by enabling a shortened spinning preparation process for rotor and airjet applications without compromising on quality. In rotor spinning, the IDF 3 helps to improve yarn quality levels, especially when processing raw materials with high short fiber content. A new can changing system increases card efficiency by up to 3%. With its advanced measuring devices, more homogenous slivers and a higher yarn quality can be achieved. Overall, the IDF 3 enables a more compact setup that saves energy, space, and resources. Customers appreciate the machine’s user-friendly operation and its ability to achieve high-speed spinning in combination with the TC 30i card.

Trützschler Card Clothing

Trützschler Card Clothing (TCC) is excited to present its broad product portfolio at ITMA Asia in Singapore. From high-precision standard components to customer-specific innovations, TCC turns challenges into solutions by delivering technologies that combine precision and versatility, tailored for every application and individual customer need. All card clothings are specifically engineered and precisely aligned with Trützschler machines and processes – ensuring a high carding performance and consistent quality.

Trützschler Nonwovens

Trützschler Nonwovens will showcase its expertise in hydroentanglement, needle-punching, and Air-Through Bonding (ATB). In the field of hydroentanglement, visitors can learn more about the Carded Pulp (CP) nonwovens line which combines paper-grade pulp and viscose to produce 100% biodegradable nonwovens for sustainable wipes. For needle-punching, Trützschler Nonwovens will provide an overview of the T-SUPREMA needle-punching line that stands out for its flexibility, productivity and stability across technical applications such as automotive, filtration, geotextiles, and acoustics.

The Trützschler Nonwovens experts will share insights into a groundbreaking advancement in ATB technology: the world’s only industrial-scale solution for processing 0.6 denier ultra-fine bicomponent fibers. This machine setup enables the production of exceptionally soft and high-performance nonwovens for premium baby diapers, including topsheets, backsheets, and absorbent distribution layers (ADL). These nonwovens meet the highest global standards for comfort, fluid management, and skin-friendliness.

Supporting all these processes, the X-Series embodies Trützschler Nonwovens’ carding expertise. The NCT-X and NC-X deliver robust, consistent quality with high output and stability, while the NC-Xe offers a cost-effective entry-level solution with built-in scalability and upgrade options.

_line-800.jpg)

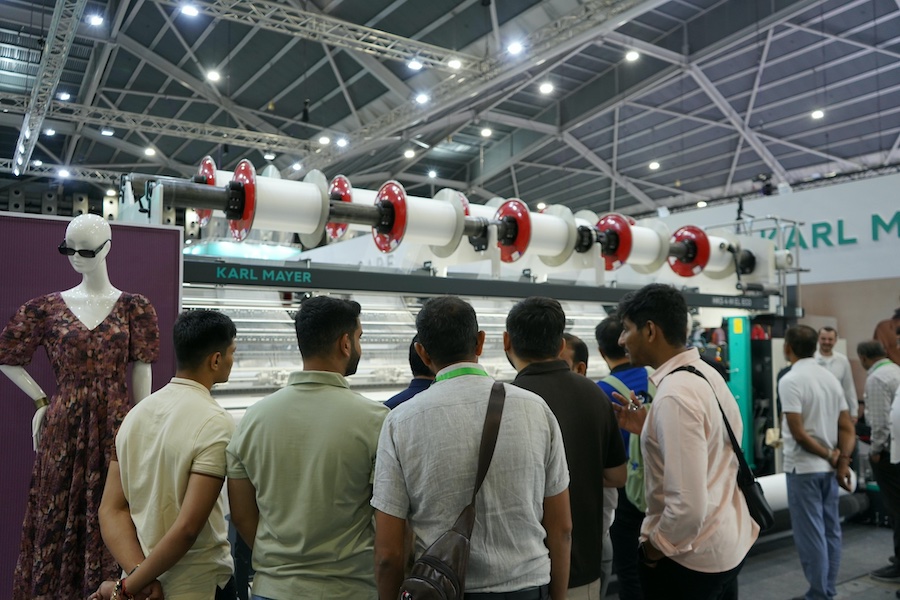

The innovation happens in Singapore

ITMA Asia 2025 is the chance to experience Trützschler’s latest innovations up close – including a never-before-seen automation solution that addresses key industry challenges. The experts from Spinning, Nonwovens, and Card Clothing look forward to welcoming interested visitors at booth D302 in Hall 4!