#Knitting & Hosiery

More speed. More patterns. More profit: two new HKS machines secure the lead

The newcomers HKS 3-M EL ECO and HKS 4-M EL ECO set new standards in the tricot market

“The HKS brand made by KARL MAYER stands for the best warp knitting machine in the world, regardless of model and manufacturing location,” says Michael Ahrendt, Product Owner Global Tricot at KARL MAYER.

The electronic guide bar control system guarantees unlimited repeat lengths, easy adjustments, and pattern changes at the touch of a button – and has been doing so for 35 years now. All three- and four-bar HKS machines that are equipped with it have been bearing only an EL in their designation since fall 2025. KARL MAYER is also expanding its successful platform: the recently launched HKS 3-M EL ECO and HKS 4-M EL ECO set new standards in terms of performance and cost-effectiveness.

HKS 3-M EL ECO – the economical gateway to the EL world

The new three-bar midrange warp knitting machine is the economical alternative to the HKS 3-M EL, formerly HKS 3-M ON. It opens up attractive volume segments and sets new standards: as the first three-bar HKS EL, it is available in working widths of up to 370″.

Thanks to the proven HKS core components, it offers the reliability, user-friendliness, and fabric quality of the high-performance machine – but at a significantly lower cost. Its working speed ensures high profitability in practice; in the future, the difference between it and the premium model will be most noticeable in terms of production speed.

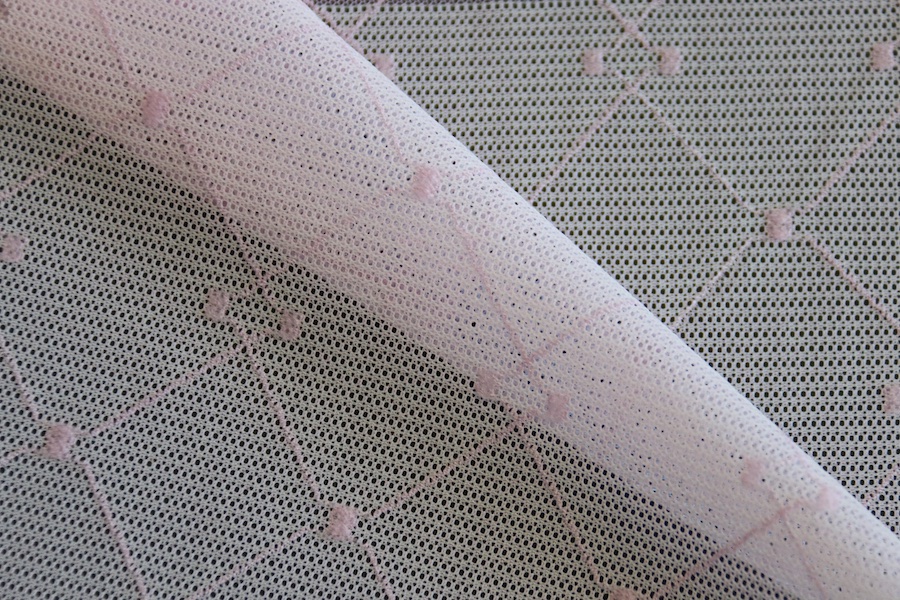

When it comes to patterning, the HKS 3-M EL ECO Next Generation offers a wide range of options: EL guide bar control, optional multi peed, and an extended shogging distance from 9 to 34 mm enable larger motifs, coarse structures, wide repeats, and greater intervals between design spots such as dots – e.g. for plissé patterns with more striking 3D effects or plush fabrics with longer pile.

The target markets for the new ECO variant are primarily automotive interiors, outerwear, sportswear, upholstery fabrics, and velour, as well as coatings and advertising textiles. The first machines have already been successfully sold to South America.

HKS 4-M EL ECO – ideal for applications with constantly changing designs and a wide variety of variants

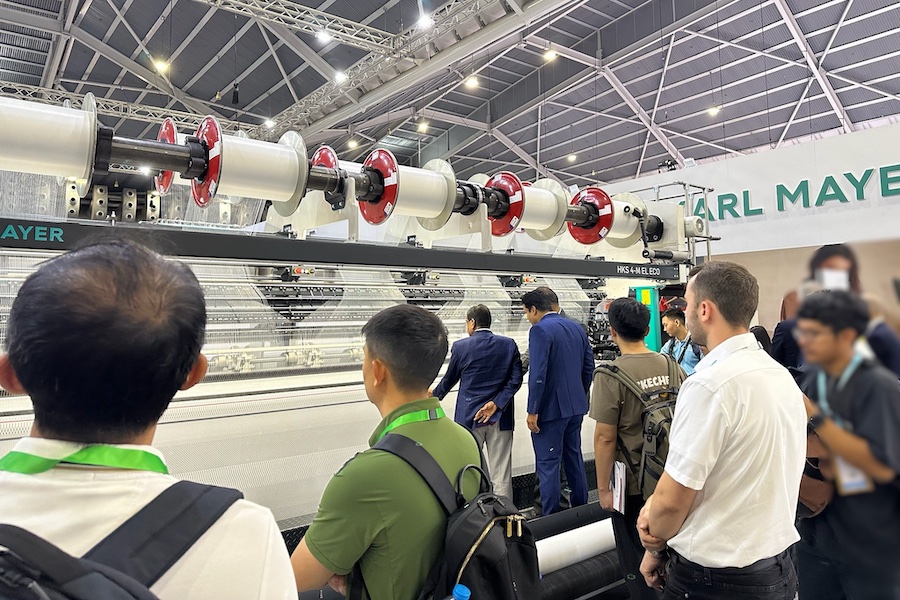

The new HKS 4-M EL ECO made a strong impression at ITMA ASIA 2025, winning over visitors with its efficiency, flexibility, and attractive price point. One of its strengths is its ability to respond quickly to demand trends. Differentiation into several variants, a shogging distance of 2″ for all four guide bars, multi speed as an option, and the EL guide bar control enable highly efficient production of popular items for a wide range of applications. The fashion industry in particular showed great interest in Singapore in the high response speed to new styles and material requirements.