#Spinning

It’s the know-how that counts

Expert technical support is a core competence for Heberlein

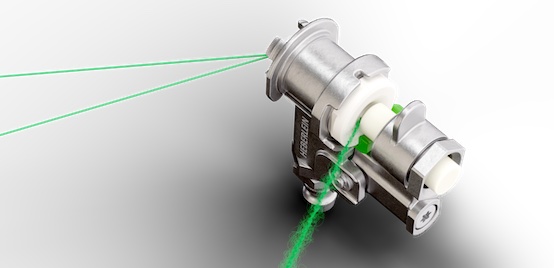

Any questions about air interlacing and air texturing jets? Heberlein customers don’t need to worry, as Samuel Gerber and his team have all the answers. Together they have over 150 years of experience in finding solutions to any challenges with synthetic continuous filament yarns. Gerber has been Head of Textile Technology at Heberlein since 2020 – and he is always proud to lead guided tours of the superb facilities he manages.

Difficult tasks

Synthetic yarn producers usually have to meet specific requirements for the end-products the market wants. And these can be difficult tasks. But Heberlein has both the know-how and the experience to turn these requirements into practical advice for efficient and sustainable production. It’s a core competence that defines the company. “Buyers demand yarn quality specifications that are clearly defined by their textile technologists. We are the competent partner for yarn producers and eager to accept this kind of challenge for our customers when they face limited resources or a lack of expertise,” says Samuel Gerber.

“For example, some customers might wish to reproduce a specific yarn, but a sample is all they have. At Heberlein, we actually like this kind of challenge, and we won’t stop until we find a way to make exactly the same yarn – or a very close alternative – as profitably as possible.”

Heberlein readily embraces another challenge: demonstrating that its jets meet the specific performance requirements in spinning. Selecting the optimal jet for a given application is a complex task. But Heberlein service technicians make the decision easier. Equipped with test jets, they visit spinning mills to conduct on-site trials until the desired outcomes are achieved. Ideally, these trials result in reduced air and energy consumption, without compromising product quality. Or they might target improved yarn characteristics – such as an increased number of knots, enhanced strength, or greater uniformity – while maintaining the same level of air consumption. This hands-on assistance in the selection and validation of the appropriate jet is highly valued by customers.

Supporting innovation

Customers trust the experts at the Heberlein Textile Technology Centre when planning new developments. The team offers indispensable support in elaborating new products by testing innovative ideas, technical specifications and other customer enquiries to be further developed in practice. Close co-operation between specialists and the availability of modern equipment and practical test procedures ensure reliable data and results. And this is the solid foundation for successful product developments in the textile industry.

”We run trials with APe, our latest DTY series, achieving significant air savings for the customer’s application,” says Gerber. “Such a result, we take as success but also as proof of the fruitful co-operation between our R&D team, our experts in the textile laboratory and the customers.”

Valuable advice on hand

At the Heberlein Textile Technology Centre, latest air interlacing, air covering, and air texturizing machines from leading manufacturers are installed, allowing for the simulation of production steps comparable to those in the customer’s own mill. Customers and their staff are always welcome to attend. That is an excellent opportunity to learn directly from experts and apply improvements to their own machinery with confidence.

Yarn tests are also highly appreciated services. Heberlein’s reports contain recommended machine settings, with photos, and in some cases customers receive woven or knitted samples or bobbins for their further evaluation. In every case, these services help yarn manufacturers to improve quality and process efficiency, to increase profitability and finally eliminate the risk of claims.

Troubleshooting is a Heberlein speciality. The team at the laboratory and test centre offers comprehensive services every day. “We support everyone – existing customers as well as any professional struggling with ATY, DTY, AC, DSY or spinning. We dare say that we can offer unique competencies in the fields of air interlacing, air covering, and air texturizing,” says Gerber.

Technical care heritage

Expert advice services have a long tradition with the company, which celebrates its 190th anniversary in 2025. Technical guidance and support have been offered as an added-value service since 1950. As a centre of knowledge for the textile industry, training and troubleshooting workshops – internal and external – are an integral part of the Heberlein offering.

Heberlein’s long heritage of sharing expertise is clearly a basis for the continuing strong customer relations policy that characterises the company today.