#Composites

Hexcel presents lightweight aerospace composite innovations at 55th International Paris Air Show

“As the aerospace industry gathers at the Paris Air Show, Hexcel will showcase its broad portfolio of innovative lightweight composite technology used across commercial and military aircraft,” said Tom Gentile, Chairman, CEO and President, Hexcel Corporation. “Hexcel’s advanced material solutions enable stronger and lighter aircraft designs, delivering extended range, greater fuel efficiency, and lower emissions. Our commitment to developing high-performance material solutions is shaping the future of flight.”

Increased output and faster production rates

In response to the aerospace industry's demand for increased output and faster production rates, several key Hexcel aerospace technologies are designed for automation and accelerated processing, offering alternatives to traditional autoclave methods.

HexPly® M51 is a new, rapid-curing prepreg developed for hot-in/hot-out press curing or stamping of primary structural composite parts. In addition to shorter curing cycles, HexPly M51 also reduces the requirement for multiple sets of tooling and labor compared with traditional prepreg systems. Fully compatible with automated tape laying (ATL), automated fiber placement (AFP) and pick-and-place processes, HexPly M51 can help OEMs meet future production targets without compromising on material performances.

Hexcel Liquid Compression Molding (LCM) products can deliver superior mechanical performance in structural aerospace components produced with infusion, RTM or C-RTM processes without the investment in autoclaves. HF610F-2 and HF640F-2 are toughened LCM epoxy resins optimised for rapid curing that, in combination with HiTape® high-performance carbon reinforcement and HiMax® carbon non crimp fabrics, provide a cost-effective out of autoclave process route for primary aircraft structures. Specially developed for continuous mixing processes, these resins can be accurately monitored by in-line mixing equipment thanks to optimized viscosity at process temperatures.

Hexcel will also promote its TowPlyTM towpreg range for filament winding applications. The combination of fast curing and high temperature resistance, make the TowPly™ products using the M901 resin with intermediate modulus IM 24K and 12K HexTow® carbon fibers a perfect solution for demanding filament winding applications in Defence and Space, Urban Air Mobility (UAM) and Civil aircraft markets.

Enhancing performance across Aerospace applications

Hexcel is also offering innovative technologies designed to meet the rigorous demands of the aerospace industry, ensuring the company remains at the forefront of delivering high-quality, high-performance, solutions for efficient manufacturing of complex components for a wide range of uses including urban air mobility.

HexTow® continuous carbon fiber remains the preferred solution for advanced aerospace applications. Using HexTow IM9 24K manufacturers have an alternative solution to maximize efficiency in primary and secondary aerospace structures. HexTow IM9 24K delivers a strong value proposition when compared to other commercially available IM fibers and compliments the additional standard, intermediate and high modulus fibers in the HexTow range.

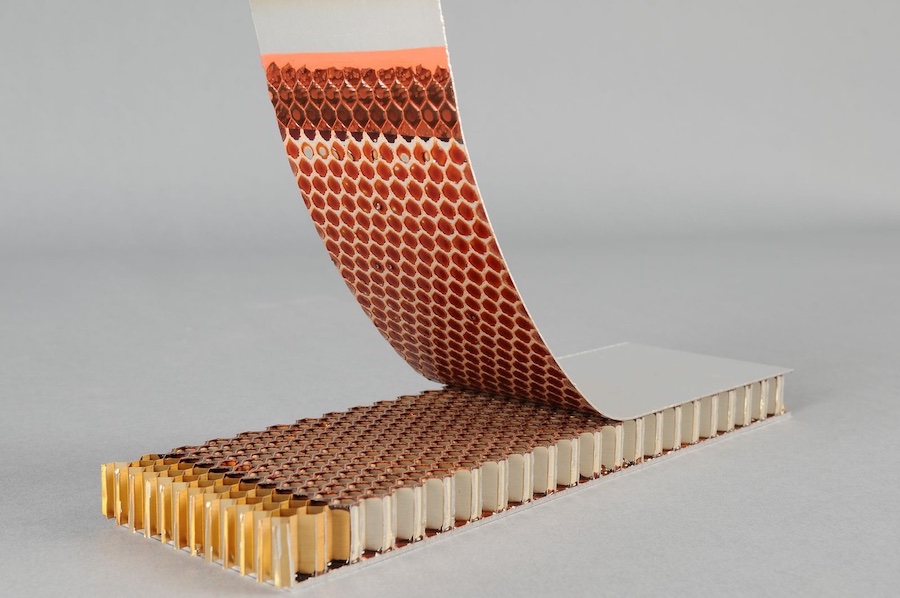

Hexcel has recently expanded its core portfolio, adding the non-metallic Flex-Core® HRH-302 mid-temperature product to its honeycomb range. Developed to offer a thermal management solution to the aerospace industry, HRH-302 is highly conformable and well suited to the complex curvatures and increasing heat loads found in next-generation aircraft nacelles. Certification is currently underway with Hexcel expecting this material to be a key enabler in future urban air mobility (UAM) and engine programs.

_hrh-302-mid-temperature_honeycomb_core-900.jpg)

Hexcel will present its HexBond® adhesives range in Paris. These materials cover the whole scope of adhesives formats (such as adhesive films, pastes, primers and surface films including M98 & others) that complete the global composite package Hexcel provides. Hexcel sees a strong integration of its adhesives in a number of new and legacy aerospace programs and consolidates its leadership position in the market by offering an adhesive range completely compatible with HexPly® prepregs, delivering proven, long-lasting reliability and outstanding mechanical performance.

Sustainability

Hexcel provides the broadest product portfolio of lightweight composite solutions for the aerospace industry and performance-oriented industrial markets. By lightweighting aircraft and other forms of transportation, fuel consumption is reduced leading to lower emissions. Hexcel composite solutions contribute to a 25% reduction in fuel consumption for the composite rich A350 and B787 aircraft as compared to prior generation aircraft. In alignment with the sustainability of our products, Hexcel is focused on operating as a responsible and low-risk business partner by minimizing our environmental impact and acting ethically.

Hexcel works continuously to develop multiple solutions to recycle and upcycle superfluous production materials as well as those created by its customers. For example, Hexcel works closely with Fairmat, with both companies demonstrating the benefits of the closed loop ecosystem for carbon fiber prepreg recycling. Fairmat uses state of the art technology to create FairPly 100% recycled customized CFRP sheets using Hexcel prepreg. This solution offers high strength and stiffness benefits, filling the gap in the advanced materials recycling industry and ensuring carbon fiber remains in use for valuable applications. This partnership has led to more than 280 tons of prepreg material being diverted from incineration and landfill to fulfilling commercial product needs in 2024.

Aerospace components and demonstrators on display will include:

+ An demonstrator component manufactured with the latest generation of lightweight UD PEKK/carbon thermoplastics. The HELUES project featured partners Arkema, Christian Karl Siebenwurst GmbH & Co. KG, New Materials Bayreuth GmbH, Airbus Helicopters Deutschland and Hexcel and has developed a novel process to create a door component using a unidirectional single layer of PEKK/carbon and a one-step over molding of PEKK/carbon ribs in less than 2 minutes.

+ HexPly M51 parts including one developed by GKN and one by Duqueine Group

+ A HexPly M91/IM8 wing component manufactured by FACC for the Archer eVTOL aircraft

+ A HexFlow®HF640 gutter component manufactured in RTM

+ A non-metallic Flex-Core® HRH-302 mid-temperature demonstrator developed to offer a thermal management solution to the aerospace industry

+ HexTow IM9 24K carbon fiber as an alternative solution to maximize efficiency in primary and secondary aerospace structures

+ TowPly™ towpreg range for filament winding applications. The combination of fast cure and high temperature resistance resin M901 with intermediate modulus IM 24K and 12K carbon fibers make TowPly™ a perfect solution for filament winding demanding applications in Defense and Space, urban air mobility (UAM), civil aircraft markets.

“With a comprehensive portfolio of high-performance solutions on display, Hexcel continues to shape the future of aerospace manufacturing delivering the materials, technologies, and expertise that enable the industry to fly faster and more efficiently,” concludes Thierry Merlot, Hexcel President Aerospace Europe, Asia Pacific, Middle East, Africa & Industrial.