#ITMA Asia + CITME Singapore 2025

The KARL MAYER Warp Knitting Business Unit at ITMA ASIA + CITME 2025

Reorientation and a strong trade fair presence

Christine Wolters, Head of Corporate Communications at KARL MAYER, spoke with him about his plans and new responsibilities in the warp knitting machine business and the highlights he and his team will be presenting to visitors at ITMA ASIA.

CW: What are your plans for your new position?

AW: At the top of my to-do list are tasks that all focus on the customer. We are refining our product portfolio so that we can serve our customers’ needs with maximum effectiveness, and we are concentrating all our capacities on projects that bring our customers the greatest added value. I am also concerned with agility in our innovation process: we are purposefully strengthening our innovative power and acting more dynamically, flexibly and responsively in our pursuit of further progress in order to ensure a successful “innovation pipeline”.

CW: That’s a challenging agenda! What can you build on to achieve it?

AW: Our employees are one of our greatest strengths. The knowledge within our company is vast. We have a large number of technical experts and a good mix of experienced professionals and young talent eager to experiment.

Our long history is important, too. Our tradition and our shared roots, which go back a long way, offer the potential for a spirit that draws on everyone being passionate about their tasks – a genuine spirit of getting things done and sticking together. My experience in my last role as head of Care Solutions showed me that with a highly committed team, a simple strategy and a clear focus on improving every day, it is possible to hold your own in a highly competitive environment.

What also continues to help us is our reputation. KARL MAYER enjoys an excellent standing in the market. We have worked hard for decades to build up our reputation and our brand. These are threatened daily by our direct and indirect competitors. Everyone at the company makes a hugely important contribution every day to protecting and maintaining KARL MAYER's reputation.

CW: So, you are well equipped to tackle the challenges ahead. What motivated you to take on this task at a personal level?

AW: I have been at KARL MAYER for almost 29 years in various positions and have always been very proud to be directly involved in this global market leader’s business success. Even in my first position as Sales Manager for the Asia-Pacific region from 1996 to 2001, I was able to set the course for the future by launching the new machine business in India and almost doubling the market share of our weft insertion warp knitting machines in Korea to 95%. Later, as Vice President Sales at KARL MAYER MALIMO, I was also able to significantly increase the market share of composite machines and, as Head of the Spare Parts Business, expand it into a core part of our business. This pride in making a difference for the company is what drives me.

The commitment shown by Mr Karl J. Mayer is truly inspiring. As a representative of the advisory board and of the Mayer family, he supports me in tackling the challenges that lie ahead. Above all, he champions the topic of innovation passionately and with a wealth of experience.

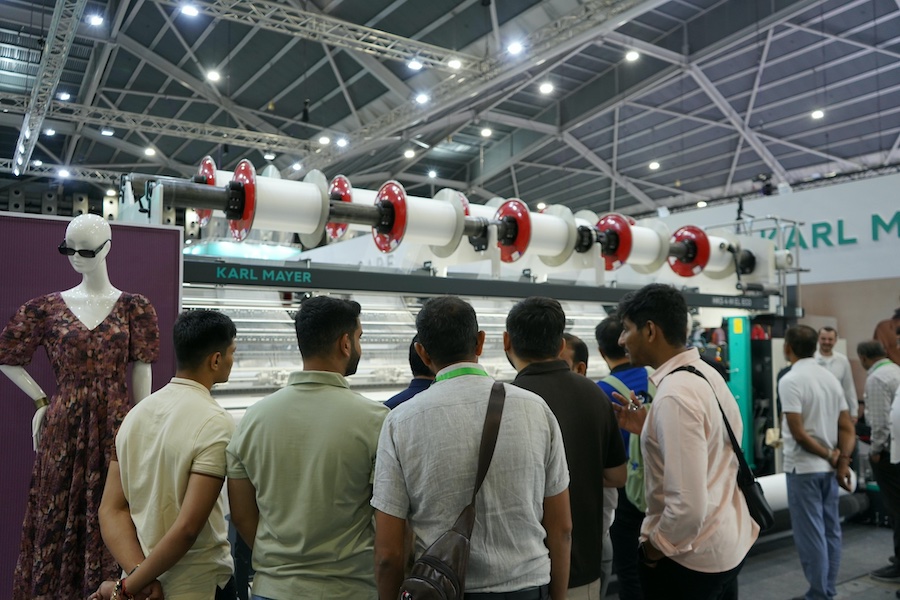

CW: Let’s take a look at the upcoming ITMA ASIA + CITME in Singapore. The trade fair format has always set the pace for innovation in the industry. What can visitors expect at the KARL MAYER booth?

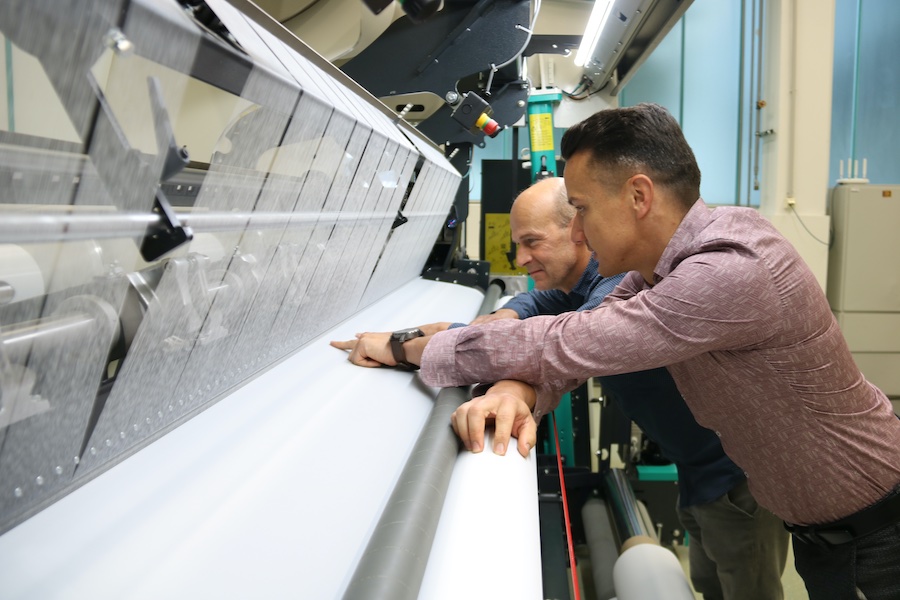

AW: KARL MAYER is once again driving forward important innovations in the field of warp knitting. We look forward to presenting to our trade fair visitors two brand new, state-of-the-art and high-performance tricot machines, which we have developed to meet the fundamental requirements of the textile industry – with maximum productivity, the highest precision and uncompromising efficiency.

The new 2-bar tricot machine for elastic fabrics is unbeatable in terms of output and speed, making it more productive than ever before. Customers also benefit from other advantages thanks to a completely new concept, including greater energy efficiency and less handling effort. I am really proud that our team can present this innovation at ITMA ASIA.

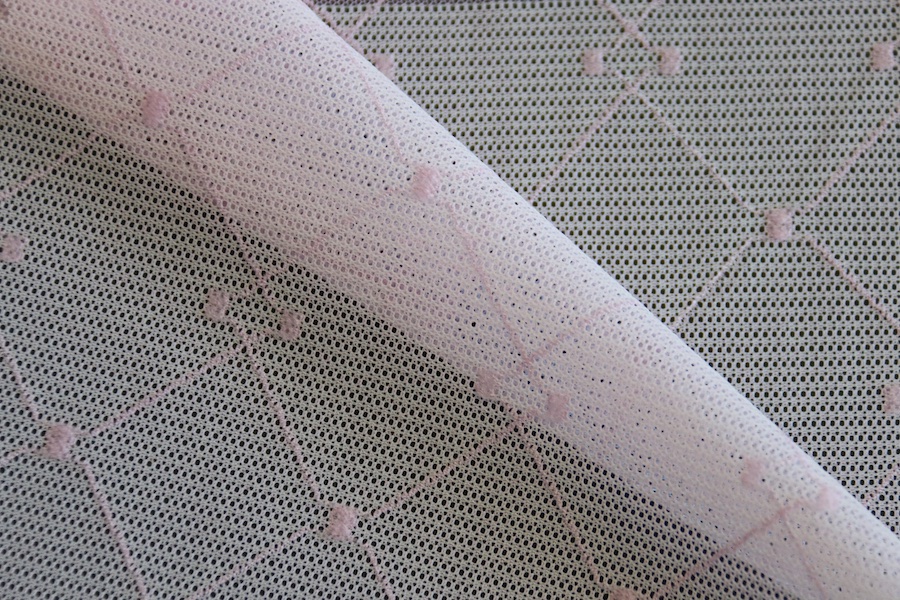

With a new 4-bar tricot machine, we are responding to the demands of price-sensitive fashion markets. The newcomer is a real brand product that impresses with its extremely attractive price-performance ratio. This is particularly interesting for manufacturers of trendy clothing items such as seersucker.

Focusing on textiles is extremely important to us. Only in this way can we provide our customers with optimal support – with machines that meet their requirements, as well as with textile expertise and application orientation. Therefore, another highlight at our booth is an inspiring textile show featuring exclusive fabrics and fashion items covering all our technological areas: tricot, lace & raschel, and spacer fabrics.

We look forward to talking about the various aspects of our innovations with our visitors.

CW: Thank you very much for this insightful conversation, and good luck to us all with the current transformation!

AW: It was a pleasure!